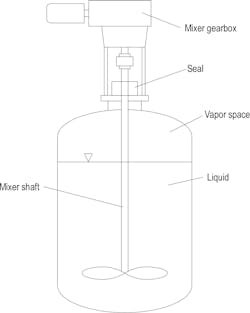

Shaft seal selection for top-entry mixers

The immediate choices of sealing technology for an application are dictated by the health, safety and environmental risks (HSE). Product containment is the primary concern. Some industrial mixing processes involve hazardous fluids entering the tank and can even produce hazardous fluids as a result of an intentional or potential chemical reaction within the tank. Product leakage to atmosphere is often the vapor above the liquid level, which can result in invisible and pervasive clouds that can harm people, reach spark or heat sources, corrode other equipment, or contaminate off-site areas downwind.

Secondary to HSE, mixer shaft offset is a practical factor in selecting seal technology for general use. For our purposes, we define offset as a shift of the shaft from its original position when the seal device was installed. (Offset does not include dynamic shaft motion.) Radial offset is the out-of-concentricity of the shaft centerline relative to the nozzle bore. Common causes of this include settling of the tank foundation and damaged steady bushing assemblies. Similarly, axial offset is upward or downward shift of the shaft. Common causes of this include relative thermal growth of the shaft relative to the tank, aging of the gearbox drive, and mechanical looseness in the shaft section couplings.

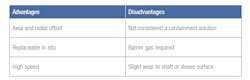

Each of the five generally accepted technologies for sealing top-entry mixer shafts is described in the following section. The basic advantages and disadvantages are listed, but there are exceptions to every statement based on the specific seal design and application. Nonetheless, these will help start a good discussion among the end user and the mixer, tank, motor and seal manufacturer.

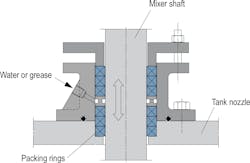

Compression packing

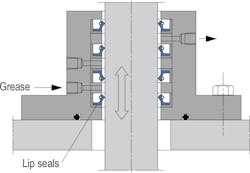

Lip seals

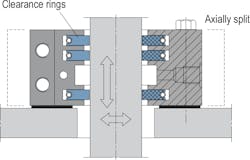

Clearance ring seals

The housing can be split into two halves so that the segmented bushings can be replaced without disturbing the mixer. Some designs also have a split wear sleeve for bushings designed to have a very slight interference during run-in.

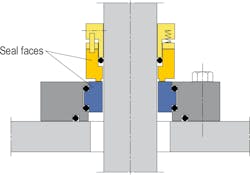

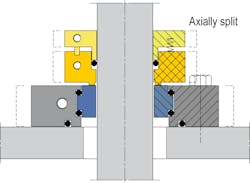

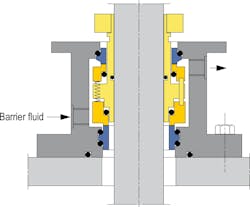

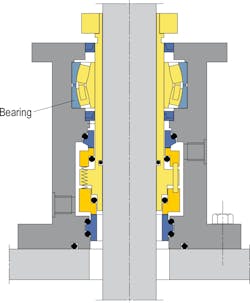

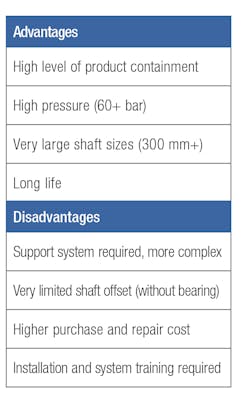

Mechanical seals

Mechanical seals are comprised of axially opposed rotating and stationary rings in direct contact or separated by an extremely thin lubricating film. There are several configurations available, such as single dry-running seals, axially split seals, and dual-pressurized liquid or gas seals.Many dual mechanical seal designs include a radial bearing in the seal cartridge to limit radial and angular excursions of the shaft during operation. Many top-entry mixing applications can be quite turbulent or create large radial forces on the mixing blades. The radial bearing in the mixer gearbox and steady bushing in the tank may be too distant from the seal to keep the shaft deflection from damaging the seal components or disrupting the thin lubricating film between the faces. This can add cost and complexity but may be the only way to achieve safe operation with high reliability and long life.

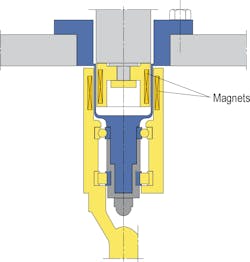

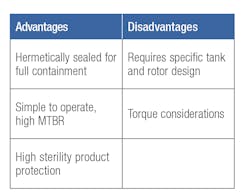

Magnetic couplings

Conclusion

The selection of the safest and most reliable seal technology for mixers is not easy. Shaft sizes range from 20 millimeters to over 400 millimeters, tank volumes from 5 liters to over 100,000 liters, and there are an enormous range of pressures, temperatures and shaft speeds.

Many industrial applications involve a sequence of mixing steps — each with its own operating parameters — so selecting one seal technology suitable for all conditions is required. It is recommended to have a detailed dialogue among the end user, mixer manufacturer, seal manufacturers and even the tank manufacturer so that a safe, reliable and cost-effective selection can be made.

John Merrill is a principal engineer with EagleBurgmann and resides in Charlotte, North Carolina. He has worked in the seal industry since 1990. Merrill received a Bachelor of Science in mechanical engineering from the University of Tulsa and a Master of Science from Western Michigan University. He is an active participant in the Hydraulic Institute, API 682, and ASM International.

Gabriel Young is a senior engineer with EagleBurgmann in Denver, Colorado. He received his Bachelor of Science in mechanical engineering from St. Louis University and has worked in the seal industry since 2012. Young is an active participant in the Hydraulic Institute.

About the Author

John Merrill

John Merrill is a principal engineer with EagleBurgmann and resides in Charlotte, North Carolina. He has worked in the seal industry since 1990. Merrill received a Bachelor of Science in mechanical engineering from the University of Tulsa and a Master of Science from Western Michigan University. He is an active participant in the Hydraulic Institute, API 682, and ASM International.

Gabriel Young

Gabriel Young is a senior engineer with EagleBurgmann in Denver, Colorado. He received his Bachelor of Science in mechanical engineering from St. Louis University and has worked in the seal industry since 2012. Young is an active participant in the Hydraulic Institute.