Exploring the possibility of limitless bearing wear

Process industries and modern manufacturing rely heavily on bearings. They are used extensively in almost every type of rotating equipment. However, rolling, rotating or sliding contact interfaces in every man-made, natural or biological system generate friction.

If not reduced or effectively controlled, high torque bearings can increase the power required to overcome the resistance and drive the equipment. This results in a greater cost to move the load and a greater energy output required to operate the equipment. In addition, a high level of friction often leads to higher wear and, ultimately, poor reliability and equipment failure.

It is clear that reducing friction is a high priority for engineers. However, bearing friction is a complicated problem, as it is not constant and is addressed using certain tribological phenomena that occur in the lubricant film between the rolling elements, raceways and cages.

It is estimated that a third of bearing failures1 can be attributed to improper lubrication. Choosing a bearing lubricant is not an optional extra — it is a fundamental part of the design process and must be expertly matched to the application requirements and operating conditions. Whether a design engineer opts for a dry, silicon or mineral lubricant, an oil or grease, the aim will be to minimize friction by reducing or preventing metal-to-metal contact between rolling elements and raceways.

While design engineers have long searched for ultra-low friction bearing technologies to reduce wear and prevent corrosion, there are new material coatings that, when used on bearings, dramatically reduce friction compared to the lubrication and surface treatment options currently on the market.

Friction is the result of microscopic imperfections in surfaces. On the atomic scale, however, friction concerns the attractive forces between individual atoms. This opens up the phenomenon of super lubricity, where the atomic scale structural mismatch makes it impossible for multiple atoms in one surface to get close to atoms in the other, leading to extraordinarily low friction.

Since super lubricity was first proposed in 1990, several researchers have observed the effect, but it has been difficult to scale because of the inconsistency between macroscopic surfaces, that is, until now.

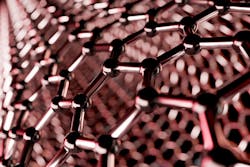

Graphene and GRM

Graphite was first used as an additive in early lubrication investigations due to its layered lattice-like properties. Graphite paste remains the most common form of solid lubricant on the market today. But, graphene is a two-dimensional material, so it offers unique friction and wear properties that are typically not seen conventionally. Besides its well-established thermal, electrical, optical and mechanical properties, graphene can serve as a liquid or colloidal lubricant for bearings and can even be applied as flakes to the surface.

A 2019 study conducted by the Institute of Machine Design and Tribology2 at Leibniz University looked to reach a conclusion regarding the frictional properties of graphene as a grease additive. It investigated the frictional torque for sliding contacts and rolling bearing application. For the latter, two bearing test rigs were used to monitor the pivoting movement for more than 1 million test cycles. The study concluded that the thickness of the graphene layers affected the coefficient of friction (COF), but all tested thicknesses reduced friction significantly.

Since graphene is ultrathin, even with multiple layers, it can be applied to systems with oscillating, rotating and sliding contacts to reduce friction and wear, as well as protect bearings from corrosion when exposed to water, a process commonly known as tribo-corrosion. This is because graphene exhibits a slippery texture, which could potentially make it an excellent lubricant.

According to a study into the tribological behavior of graphenex coated bearing steel,3 the COF of the graphene coated material was reduced by up to 200% compared to that of the uncoated material. By increasing the sliding speed, the wear rate and the average value of the COF of the graphene-coated bearing decreased.

Further studies build on this research. In addition to being low shear and highly protective, the application of graphene in bearings prevents oxidation of the steel surfaces due to its relative lack of permeability to liquids and gases. Research conducted by the U.S. Department of Energy’s Argonne National Laboratory4 shows that the small number of layers in graphene reduces not only friction in steel seven times more, but also wear-and-tear 10,000 times more, reducing tribo-corrosion.

This research may have far-reaching implications in many industries. It could help wind turbines move with greater ease, allowing them to produce more energy, and it could better seal off machinery, as it pumps oil or gas from the ground or out at sea. While the researchers at the Argonne National Laboratory have also developed a high-performance dry lubricant by combining nanodiamonds with two-dimensional molybdenum disulfide, this is a more expensive process than the graphene lubricant option.

The process of adding a graphene coating to bearings is relatively easy compared to adding a traditional lubricant — graphene does not require any additional processing steps, other than just sprinkling a small amount of solution or spraying the solution on the surface, making this process simple, environmentally friendly and cost effective. Also, graphene flakes that are added to the surface of a bearing can last a considerable amount of time due to the ability of the flakes to reorient themselves during the initial wear cycles, providing a very low COF.

In a study on the potential of graphene as a new emerging lubricant5, researchers estimated that the reduced loss of energy to friction offered by new materials would yield potential energy savings of 2.46 billion kilowatt-hours per year, equivalent to 1.5 million barrels of oil.

Conclusion

Graphene and its tribological potential as a bearing lubricant remains relatively unexplored, with few investigations into its use as a self-lubricated solid or as an additive for lubricating oils. However, innovations in graphene and newly discovered materials have real potential as lubricants for bearings and, once fully developed, could have positive impacts on many mechanical applications that could lead to tremendous energy savings.

Resources

- Bearing Damage and Failure Analysis, SKF. https://www.skf.com/binaries/pub12/Images/0901d1968064c148-Bearing-failures---14219_2-EN_tcm_12-297619.pdf.

- Investigations on Graphene Platelets as Dry Lubricant and as Grease Additive for Sliding Contacts and Rolling Bearing Application. Institute of Machine Design and Tribology, https://www.mdpi.com/2075-4442/8/1/3/htm.

- Tribological Behaviour of Graphene Coated Bearing Steel (EN31). R Moharana et al 2019 J. Phys.: Conf. Ser. 1240 012040. https://iopscience.iop.org/article/10.1088/1742-6596/1240/1/012040/pdf.

- Argonne National Laboratory. https://www.anl.gov/article/slippery-when-dry.

- Graphene: A New Emerging Lubricant. Diana Berman, Ali Erdemir, and Anirudha V. Sumant. Materials Today. https://doi.org/10.1016/ j.mattod.2013.12.003.

Chris Johnson is managing director of EZO bearings supplier SMB Bearings. He has held this position for over 10 years, as a specialist in bearing and lubrication services. For more information, visit smbbearings.com.