Why Burullus and Rashpetco continue to invest in subsea wetgas meters for Egypt’s West Delta Deep Marine concession

The objective of the Burullus Gas Company, which is a joint venture in Egypt between the Egyptian General Petroleum Corporation, Shell and Petronas, is to undertake exploration and field development operations on behalf of West Delta Deep Marine (WDDM) concession holders. The company produces natural gas for both the domestic Egyptian market as well as export markets.

The WDDM area was developed in multiple stages since 2003 and has 68 subsea wells. The first phase was equipped only with Venturi meters, but later on the company realized the importance of having an accurate measurement of each phase in the flow stream (gas, condensate and water).

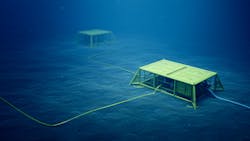

Burullus Gas Company has successfully deployed Emerson’s Roxar Subsea Wetgas Flow Meters on more than 60 wells off the coast of Egypt, in the WDDM area of the Mediterranean Sea. The Roxar Subsea Wetgas meter has proven time and time again that it can withstand the rigors of subsea natural gas production.

Why well flow rate measurement is important to Burullus Gas Company

Producing natural gas from subsea assets is very different from producing natural gas on land. Operators are presented with specific requirements and unique challenges when building a wellsite on the seabed. Subsea settings present some of the toughest field operating conditions in the world, such as low temperatures, water pressure and accessibility. Reliable flow metering is a key factor in the effective management and optimization of these complex reservoirs.

There is no room for chance or errors in high-risk, deep-water environments. Only the most advanced and purpose-built technologies should be used to maintain flow assurance and integrity. In subsea environments it is essential to optimize the production to delay water breakthrough and reduce the risk of hydrate plugs forming in low temperatures.

Furthermore, obtaining accurate readings of produced gas is necessary to ensure that wells are optimized to stay within safe operating limits. Therefore, the objectives of individual well metering are as follows:

Production allocation:

- Allocated production is used as an input for history matching for reservoir simulation models, Material Balance Analysis (MBAL) and for updating and maintaining gas in place estimates.

- Since WDDM was developed over a long period of time, wells were installed in different phases based on different commercial agreements. To ensure accurate ownership allocation of the gas produced, it is necessary to obtain accurate and trustworthy readings.

Well and reservoir management:

- Understanding zonal contributions, to allow shut in or choke back of high-water producing intervals with inflow control valves (ICVs).

- Management of wells and their individual zones within their well operating envelope (WOE). The envelope needs to allow for metering uncertainty — a higher metering uncertainty leads to a more constrained envelope and would constrain production.

- Over the decades that Burullus has held the concession in the West Delta Deep Marine area, they have found that one of the main recurring issues was produced water in the flow. Being able to detect water early is critical, as water can quickly lead to high-risk situations such as the formation of hydrate plugs in the icy deep-water temperatures.

- Hydrates can form very fast and lead to plugging of the flowline. To break up a hydrate plug before it becomes a problem requires the injection of chemicals. But here too, it is essential to know how much to inject so it solves the problem without causing a new one. A hydrocarbon mixture that has too much of injected chemicals in it, means a loss of money as there will be unnecessary quantities of chemical used. The optimum chemical concentration to prevent the hydrate formation requires accurate measurements of the water flow rate.

Developing a solution

Burullus Gas Company needed a solution for the WDDM reservoir that could provide continuous flow measurement on a well-by-well basis. The company needed to accurately measure gas and detect water breakthrough to optimize chemical injection when needed to prevent hydrate plugs.

In early 2002, the company evaluated a number of metering options, such as, differential pressure meters, multiphase meters and wet-gas meters. In almost every instance, the company rejected the offered solution.

They found that differential pressure meters, for example, were not up to the challenge of the changing flow composition, meaning readings were not reliably accurate specially for gas condensate and after water breakthrough. Not having accurate readings would reduce reaction time and increase the risk of detecting the early water breakthrough.

Multiphase flow meters were also considered unsuitable because of the high liquid flow uncertainty in ultra-high gas volume fraction (GVF) wells found in the West Delta Deep Marine area.

Burullus concluded that dedicated wetgas meters were the only reliable option and selected the Roxar Subsea Wetgas Flow Meter from Emerson.

The Rashpetco Petroleum engineering staff favors one flow meter per well. This is because experience has shown that during subsea communications challenges, data from wells can be inaccessible. That meant Rashpetco did not have any flow data from the well, making it harder to determine production differences and well allocation (i.e., shutting in a well to monitor the impact on total production). This is not an accurate methodology as it depends on the number of wells on the stream. It is also very costly because a shutdown means production deferral. This is why Burullus maintains one Roxar Subsea Wetgas Meter per well.

The Roxar flow meters have proven to be an ideal solution for the WDDM’s specific challenges.

Experience has shown that these subsea meters can be relied upon to provide early warning of water breakthrough which allows the well to be optimized. This has happened more than once. The other challenge has been maintaining a smooth execution of the ownership allocation, which the accuracy of these subsea meters has allowed.

There have been no failures in the Roxar Subsea Wetgas Flow Meter, and there has been no need for regular or intensive maintenance service due to the robust design and commissioning of the device. This has proven an added benefit of selecting this particular flow meter.

Flow rate calculation and pressure volume temperature optimization

Almost 60 wells in the WDDM concession are equipped with a Roxar Subsea Wetgas Meter. Subsea wetgas meters are able to measure individual well production rates (gas, condensate and water), which are used for well production allocation.

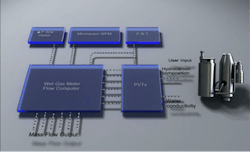

The Roxar Subsea Wetgas Meter is an instrument that measures accurate water volume fraction and total hydrocarbon flow rates, within a very compact design. The system evolved from well-proven Roxar technology developed from the Roxar Water cut meter. In addition, formation water detection enables the meter to provide indication of formation water in the fluid stream. The indication is retrieved from the microwave measurement device and gives valuable information for both reservoir and process management. The picture below shows the Roxar Subsea Wetgas Meter measurement concept.

The flow through the meter is measured using the differential pressure over a cone. Increasing flow results in an increasing differential pressure (Bernoulli’s theory). The measured differential pressure basically depends on fluid density, composition and flow velocity. A PVT software package is integrated as part of the Roxar Subsea Wetgas Meter software. The package is called PVTx and is manufactured by Emerson/Roxar. The key user input data to the meter are the fluid composition and water conductivity.

The flow rate calculation in the meter starts with determining the water volume fraction (WVF) using the microwave technology. If formation water is present, Salinity index (SI) will increase, which gives an indication of the onset of the production of formation water and appropriate actions can be taken (recently observed in one of WDDM wells).

After defining the WVF, the remaining mass flow rate is the hydrocarbon mass flow rate, and by using the PVTx software package in the meter it will flash the fluid composition at the meter condition to determine the percentage of the gas and condensate in the hydrocarbon stream thereby calculating the flow rate of each phase (gas, condensate) at standard conditions. Burullus has used the meter with more flexibility to change the initial PVT set especially in case of production from dual zone wells that has a different fluid composition.

Looking to the future

With the proven track record of measurement reliability, alerting operators to potentially hazardous flow conditions, the Burullus Gas Company prefers to install a Subsea Wetgas Flow Meter on each individual well going forward. Having the right technology from the start ensures production is running at peak performance and potential problems can be taken care of before they can impact the process.

With the strict reporting requirements for each individual well, knowing they have access to real-time accurate data makes it easier to be able to meet allocation accounting and natural gas obligations for both domestic Egyptian and international customers.

When it comes to subsea gas applications, operators need the most advanced solution on the market. Precision technologies like the Roxar Subsea Wetgas Meter empower producers to meet the challenges of these reservoirs without compromising safety, sustainability or productivity of the subsea field.

Mogahed Mohamed, petroleum engineering manager at Rashpetco, has been with the company for over 20 years. He is experienced in working in offshore gas fields and developing subsea systems. He was involved in eleven development phases for WDDM concession, including base of design, assurance, and execution and start up, providing input for all proposed development and infill wells including proper description and location of subsurface target reservoirs and predicted reservoir properties.

Hossam Said, senior reservoir engineer at Rashpetco, has more than 13 years of experience in oil and gas exploration and production operations, management, and petroleum engineering studies for offshore gas fields in the Mediterranean Sea. Said’s experience includes reservoir engineering analysis of mature fields producing gas, and the exploration and development of new fields, and he has a broad knowledge of sub-sea gas-well operations that includes planning and executing workovers.

Mohamed Anwar, senior manager subsea services and business development manager for Emerson’s Roxar flow measurement products, has been with the company for over 15 years. Anwar’s previous roles with Emerson’s Roxar products include service engineer, product advisor, service project manager, subsea service manager and currently business development manager for Roxar subsea wetgas meter.

About the Author

Mogahed Mohamed

Petroleum engineering manager at Rashpetco

Mogahed Mohamed, petroleum engineering manager at Rashpetco, has been with the company for over 20 years. He is experienced in working in offshore gas fields and developing subsea systems. He was involved in eleven development phases for WDDM concession, including base of design, assurance, and execution and start up, providing input for all proposed development and infill wells including proper description and location of subsurface target reservoirs and predicted reservoir properties.

Hossam Said

Senior reservoir engineer at Rashpetco

Hossam Said, senior reservoir engineer at Rashpetco, has more than 13 years of experience in oil and gas exploration and production operations, management, and petroleum engineering studies for offshore gas fields in the Mediterranean Sea. Said’s experience includes reservoir engineering analysis of mature fields producing gas, and the exploration and development of new fields, and he has a broad knowledge of sub-sea gas-well operations that includes planning and executing workovers.

Mohamed Anwar

Senior manager subsea services and business development manager for Emerson’s Roxar flow measurement products

Mohamed Anwar, senior manager subsea services and business development manager for Emerson’s Roxar flow measurement products, has been with the company for over 15 years. Anwar’s previous roles with Emerson’s Roxar products include service engineer, product advisor, service project manager, subsea service manager and currently business development manager for Roxar subsea wetgas meter.