Case study: How a Permian oil company improved its process efficiency with an inline gas ultrasonic flowmeter

For upstream oil and gas production companies — specifically Permian oil well operators — measurement instrumentation on a three-phase separator presents many challenges in terms of installing accurate equipment while minimizing maintenance and total cost of ownership. The Proline Prosonic Flow G ultrasonic flowmeter from Endress+Hauser helped one company increase diagnostic availability, reduce maintenance and optimize the allocation measurement processes.

The challenge

Permian oil wells typically produce a mixture of oil, water and gas that goes through a three-phase separation process to separate and measure each fluid. High quality and reliable instrumentation is essential to help allocate fluid components to each well. In most oil and gas separation processes, the gas is measured with a multivariable differential pressure flowmeter or turbine meter connected to a separate flow computer to perform the proper calculations back to standard reference conditions. These flowmeters require regular maintenance and inspection to ensure accuracy but provide limited diagnostics of process upsets.

Another challenge operators face is the decline in production of shale wells. These wells have an exponential reduction in production. Shortly after the initial flow back and production, the flow rates decrease dramatically. Orifice plates for differential pressure flowmeters only offer roughly a 5:1 turndown. And after a few months of the initial output, operators must change orifice plates to ones with a smaller beta ratio to ensure accurate gas flow measurement.

Operators also need diagnostics with flow measurement to help optimize the process. If there are any process upsets, such as liquid carryover or buildup, differential pressure or turbine meter technologies have limited diagnostic capabilities to identify such issues. Problems are either found by an operator inspecting the facility in person or at the end of the month when measurement values seem inaccurate. Orifice plates must also be pulled and inspected to ensure they are clean and produce the proper dP. Any change in the plate will change the dP and, therefore, the uncertainty of the flow measurement. In many instances, turbine meters can become clogged with trash or other debris and eventually could require maintenance on the blades due to the mechanical design of the technology.

One Permian basin operator had an issue where chemicals used in the well-stimulation process caused a significant buildup in the gas lines.

The solution

The Proline Prosonic Flow G along with its Heartbeat Technology — a patented Endress+Hauser diagnostics, verification and monitoring function — allowed the Permian basin operator to identify the problem immediately, change chemicals and clean the lines.

Here’s how.

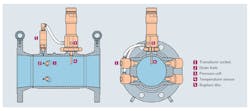

Holistically, the Proline Prosonic Flow G is an inline ultrasonic flowmeter that uses pairs of sensors fitted across from each other that transmit ultrasonic signals back and forth across the pipe. The time differential of the ultrasonic signal transit in the downstream direction with the flowing gas compared to the transit upstream against the flowing gas is proportional to the flowing velocity of the gas. The flowmeter can then calculate the proper flow rate of gas from the flowing velocity. The flowmeter is also fitted with integrated pressure and temperature sensors to help correct measured values to standardized conditions.

The Proline Prosonic G flowmeter is also designed to perform even in the presence of wet gas. The flowmeter is manufactured with large transducer sockets to help mitigate acoustic bridging of sensor to flowmeter body from condensation or moisture in wet gas streams. Chamfered sockets and drain holes in the flowmeter body also help to build up any liquids from remaining trapped in sensor pockets and interrupting flow measurement.

A traditional turbine or differential pressure flowmeter with an orifice plate may have yet to identify the same issues the customer faced. Whether volumes increase or decrease, it typically requires an orifice plate change. However, with the Proline Prosonic Flow G, this is different. The instrument is incredibly accurate at the low flow velocity range.

Further, the Proline Prosonic Flow G has a patented gas analysis application package which calculates natural gas standardized conditions according to AGA or ISO standards. It also uses a combination of pressure, temperature and sound velocity measurements to determine reference density for accurate volumetric compensations in real time, allowing for more accurate measurements in processes with changing gas compositions. Here, the instrument can be used in a separator installation without requiring an additional flow computer to perform the standardized calculations.

With Heartbeat Technology, the Proline Prosonic Flow G provides 24/7 diagnostics and proactive, predictive maintenance on the operator’s instruments. This technology enables remote access to diagnostic information, cutting back personnel’s time in the field. The Proline Prosonic Flow G will allow for a more cost-effective, safe and reliable gas measurement.

In addition, ultrasonic technology becomes especially beneficial when the operating pressure drops very low. In cases of depleting operating pressure, alternative technology, such as differential pressure orifice meters, can become inaccurate. The high turndown capability of the Proline Prosonic Flow G and 133:1 at total accuracy helps it perform optimally in applications with low flow or changing conditions.

The Proline Prosonic Flow G uses the same electronics, user interface and spare part components as Endress+Hauser Coriolis and electromagnetic flowmeters. This means a customer can standardize all three flow measurement points on a three-phase separator. This reduces required spare parts for field equipment and training for operators and technicians working with the technology. What’s more, the instrument can also be used in upstream flare measurement, gas blending, VRU gas measurement and many other applications.

All in all, for upstream oil and gas companies, the Proline Prosonic Flow G helps improve their operations with increased diagnostics, higher turndown and built-in gas analysis functionality while measuring gas composition changes in real-time to improve the accuracy of gas flow measurement.

Mason Flannery is a Product Marketing Manager for Flow Measurement products at Endress+Hauser. He started his career with Endress+Hauser in the Rotational Engineering Program and has spent time in Tech Support, Inside Sales, Application Engineering, and as a Regional Flow Product Business Manager. Mason has extensive field experience with flow measurement in industrial environments and a wide range of application knowledge. He holds a BS in industrial distribution from Texas A&M University.

Endress+Hauser

About the Author

Mason Flannery

Flow Product Marketing Manager at Endress+Hauser USA

Mason Flannery is a Product Marketing Manager for Flow Measurement products at Endress+Hauser. He started his career with Endress+Hauser in the Rotational Engineering Program and has spent time in Tech Support, Inside Sales, Application Engineering, and as a Regional Flow Product Business Manager. Mason has extensive field experience with flow measurement in industrial environments and a wide range of application knowledge. He holds a BS in industrial distribution from Texas A&M University.