Choosing the right flowmeter: Inline vs. insertion style thermal mass flowmeters

All thermal mass flowmeters serve the same fundamental purpose — accurate gas mass flow measurement based on thermal dispersion principles. However, they come in different physical configurations to accommodate various installation requirements.

How thermal mass flowmeters work

Before discussing configuration differences, it’s important to understand that all Sage thermal mass flowmeters:

- Measure gas mass flow based on the same thermal dispersion principle

- Provide direct mass flow measurement without requiring pressure or temperature compensation

- Deliver high accuracy, wide turndown ratios and excellent repeatability

The primary difference between an inline meter and an insertion meter lies in how they’re installed.

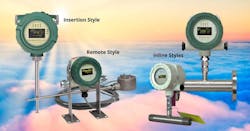

Insertion style flowmeters

What is an insertion flowmeter?

An insertion-style thermal flowmeter features a probe that inserts directly into the process pipe through a valve assembly or compression fitting.

Key features of insertion flowmeters:

- Installation flexibility: Can be installed in existing pipes with minimal modification

- Removal without process shutdown: When installed with an isolation valve, the meter can be removed for cleaning or inspection without shutting down the process

- Cost-effective: Often more affordable, especially in larger pipe sizes

- Adaptability: Can be relocated to different measurement points if needed

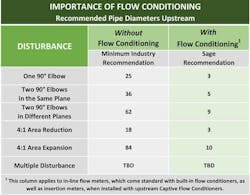

- Straight run requirements: Typically requires 15-25 pipe diameters of straight run upstream to achieve optimal accuracy when flow conditioning is not present

Optimizing insertion meter performance with captive flow conditioners

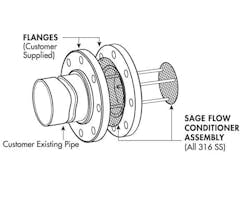

For applications where sufficient straight run isn’t available, Sage recommends using a Captive Flow Conditioner assembly with insertion-style meters.

The Captive Flow Conditioner assembly consists of:

- Two flow conditioner plates positioned between two flanges

- A mounting point for the insertion meter

- An engineered design that creates a uniform flow profile

Benefits of using a Captive Flow Conditioner:

- Reduces straight run requirements significantly

- Creates a consistent measurement profile even in non-ideal piping configurations

- Enables insertion meters to achieve accuracy comparable to inline meters

- Maintains measurement integrity in space-constrained installations

Inline flowmeters

What is an inline flowmeter?

The inline (or in-line) flowmeter includes a complete flow body that integrates into your process line as a spool piece.

Key features of inline flowmeters:

- Built-in flow conditioning: Integrated flow conditioning elements optimize gas flow profiles

- Reduced straight run requirements: Significantly reduces requirements when compared to a meter without flow conditioning

- Optimized for small pipes: Particularly effective for pipe sizes under 2 inches in diameter

- Fixed position: Permanently installed at a specific measurement point

- Precision engineering: The flow body is designed specifically for the application’s flow range

Remote configuration: Enhancing access and readability

Both inline and insertion meters are available in remote configurations, where the electronics and display are separated from the sensor.

Benefits of remote configuration:

- Display can be mounted in an easy-to-access location

- Sensor can be installed in hard-to-reach or hazardous locations

- Available with up to 1000 feet of lead-length compensated cable

- Ideal for high-temperature applications or areas with excessive vibration

Selection guide: Which configuration is right for your application?

When selecting between inline and insertion configurations, consider:

- Pipe size:

- Smaller pipes (under 2 inches): Inline typically preferred

- Larger pipes (2 inches and above): Insertion is often more economical

- Installation constraints:

- Limited straight run: Inline or insertion with Captive Flow Conditioner

- Need for occasional removal: Insertion with isolation valve

- New installation vs. retrofit: Inline for new, insertion for retrofit

- Budget considerations:

- Initial cost: Insertion is typically lower, especially in large pipes

- Installation cost: Insertion usually requires less modification

- Long-term maintenance: Both have excellent longevity with no moving parts

- Application requirements:

- Highest precision needs: Either configuration when properly installed

- Temporary measurement: Insertion with compression fitting

- Permanent installation: Either configuration is suitable

About the Author

Fred Whorff

Vice President of Sales & Business Development for Sage Metering

Fred Whorff is the Sage Metering president. He has over 30 years of experience in product design and applications of flow measurement and control products. He holds patents on several flow technologies. As a hands-on engineer, he also has considerable field experience in various industries.