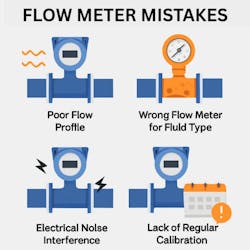

Accurate flow measurement is critical across a wide range of industries — from oil and gas to food and beverage, pharmaceuticals and chemical processing. Yet even the most advanced flowmeter can produce inaccurate readings if it is installed incorrectly, applied in the wrong conditions or left unmaintained. These common mistakes not only compromise measurement accuracy, but they can also lead to downtime, lost product and compliance violations.

In this article, we will break down the most common flowmeter errors and offer practical tips to avoid them — ensuring your system performs reliably and consistently over time.

Installation errors

Poor flow profile/inadequate straight pipe length

One of the most overlooked aspects of flowmeter performance is the flow profile entering the meter. Turbulence caused by valves, elbows or pumps upstream can distort flow and lead to erratic readings — especially with velocity-based meters such as turbine or ultrasonic types.

Avoidance tip: Follow manufacturer recommendations for upstream and downstream straight pipe lengths. A common rule of thumb is 10 diameters upstream and 5 diameters downstream (10D/5D). Flow conditioners or straightening vanes can also help if space is limited.

Incorrect orientation

Flowmeters are designed to operate in specific orientations. Installing a meter vertically instead of horizontally — or vice versa — can trap air or allow solids to settle, which throws off readings. Some meters are gravity-sensitive and require correct positioning to work properly.

Avoidance tip: Always install the flowmeter in the orientation specified in the product manual. Double-check that the arrow indicating flow direction matches the actual process flow.

Vibration or pipe stress

Mechanical stress or vibration from surrounding equipment or pipe movement can damage flow sensors and affect meter performance over time.

Avoidance tip: Use proper mounting supports to reduce vibration, and ensure there is no mechanical strain at the connection points. Flex connectors can help isolate the meter from external stress.

Application mismatches

Wrong flowmeter for the fluid type

Not all flowmeters are suited for every application. Using a turbine flowmeter on a fluid with high viscosity or particulates, for example, can cause premature wear or inaccurate measurements.

Avoidance tip: Make sure the flowmeter is compatible with your fluid’s properties — such as viscosity, temperature, chemical composition and cleanliness. Check the materials of construction and sensor type for chemical resistance and physical durability.

Flow rate out of range

Flowmeters have a defined operating range. Operating above or below this range reduces accuracy and can damage the meter.

Avoidance tip: Select a meter with a flow range that matches your process. Avoid sizing too large “just in case” — a meter operating far below its minimum threshold can produce erratic signals.

Signal and output issues

Electrical noise interference

Signal cables running too close to high-voltage lines or motors can introduce noise, leading to data spikes or loss of signal.

Avoidance tip: Use shielded signal cables and maintain separation from power wiring. Proper grounding and cable routing are essential, especially in industrial environments with VFDs or large motors.

Incorrect output configuration

If the analog or pulse output is configured incorrectly, the flow data received by your controller or PLC will be inaccurate — even if the flowmeter itself is working fine.

Avoidance tip: During commissioning, verify all output settings, signal scaling, and wiring connections. Use a test meter or signal simulator to confirm output values match flow rates.

Environmental factors

Temperature extremes

Operating a flowmeter outside its specified temperature range can cause sensor drift or total failure — especially in cryogenic or high-temperature environments.

Avoidance tip: Select flowmeters with built-in temperature compensation if working in fluctuating or extreme conditions. Use enclosures or heat tracing where appropriate.

Ingress or moisture

Moisture from condensation, washdowns, or accidental splashes can damage electronics, especially in outdoor or sanitary environments.

Avoidance tip: Choose flowmeters with the right ingress protection (IP) rating. Seal all cable entries properly and avoid placing meters where water can pool or condense.

Calibration and maintenance oversights

Lack of regular calibration

Even the most precise meters drift over time due to wear, environmental conditions or sensor degradation. Without routine calibration, data reliability can gradually erode.

Avoidance tip: Set up a regular calibration schedule based on your meter type, operating hours and industry requirements. For critical applications, annual or semi-annual calibration is recommended.

Build-up or fouling

Over time, residue, scaling, or debris can accumulate on sensor surfaces — especially in systems with dirty fluids or inconsistent cleaning.

Avoidance tip: Install upstream filters or strainers to reduce particulate load. Schedule periodic cleaning, especially in food, beverage and pharmaceutical processes where buildup is more common.

Conclusion

Flowmeters are only as accurate as their application, installation and maintenance allow. While most devices today are built for durability and precision, the most common sources of error are human and environmental — not technological.

By paying close attention to installation best practices, selecting the right meter for your fluid and flow conditions, and committing to regular maintenance, you can avoid costly measurement errors and keep your systems running smoothly.

About the Author

Mark Weiss

Marketing Specialist, Turbines, Inc.

Mark Weiss is a marketing specialist at Turbines, Inc.