How temperature, pressure and viscosity affect flow measurement

Key Highlights

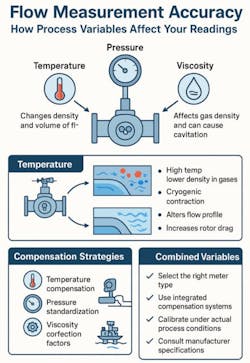

- Flow measurement accuracy is significantly affected by process variables such as temperature, pressure, and viscosity, which can alter fluid properties and meter performance.

- Temperature changes influence fluid density and volume, requiring temperature-compensated meters or real-time correction methods for precise readings.

- Pressure fluctuations impact the density of gases and can cause mechanical deformation in meters, making pressure compensation essential for accurate measurement.

- Viscosity variations affect flow profiles and meter interactions, with different meter types offering varying degrees of tolerance to viscosity changes.

- Implementing multi-variable compensation systems that integrate temperature, pressure, and viscosity sensors enhances measurement reliability and reduces errors in complex environments.

Imagine this: an engineer is reviewing flow data from a custody transfer application. The flowmeter in use is a high-quality, precision-calibrated unit. Yet, the readings fluctuate more than expected. The equipment appears to be functioning correctly, but the numbers are still off. In many cases, the issue is not the flowmeter itself but the process conditions surrounding it.

Flow measurement accuracy plays a critical role in process efficiency, product quality and regulatory compliance. In industries such as oil and gas, pharmaceuticals and chemical manufacturing, even small inaccuracies can result in significant financial losses or operational issues. Three key process variables — temperature, pressure and viscosity—are among the most influential factors that can affect readings.

In this article, we will take an in-depth look at how each of these variables impacts measurement accuracy and discuss strategies to compensate for them in real-world applications.

The role of process variables in flow measurement

Understanding process variables

Process variables refer to measurable physical properties of a system that can influence performance and output. In flow measurement, the most critical variables include temperature, pressure and viscosity. These factors are often interconnected, and changes in one can affect the others.

Why they matter

Flowmeters are calibrated under specific conditions. When process conditions deviate from those parameters, readings may shift. For example, a turbine meter calibrated at room temperature may behave differently when exposed to extreme heat or cryogenic conditions. For industries dealing with custody transfer or precise dosing, even a small deviation can create costly consequences.

Temperature effects on flow measurement

How temperature changes media properties

Temperature directly influences the density and volume of fluids and gases. As temperature increases, liquids generally expand and gases become less dense. This change affects the speed at which the fluid moves through a flowmeter, potentially altering the accuracy of readings.

For example, cryogenic hydrogen behaves very differently compared to high-temperature steam. In cryogenic conditions, materials contract and the fluid’s density increases. In high-temperature steam systems, density decreases significantly, which can affect the calibration of the flow meter.

How temperature affects the flowmeter itself

Temperature changes can also cause physical expansion or contraction of the flowmeter’s components. In turbine meters, expansion may slightly alter the rotor’s clearance, while in electronic sensors, temperature can cause signal drift or increased electrical resistance.

Compensation strategies

- Temperature-compensated meters: Some flowmeters are designed with built-in temperature sensors that automatically adjust readings.

- Integrated temperature measurement: Installing separate temperature probes in the process line and linking them to a flow computer allows for real-time correction.

- Calibrate for operating conditions: For critical applications, calibrating the meter under the actual temperature conditions of operation can significantly improve accuracy.

Pressure effects on flow measurement

How pressure changes media properties

Pressure has a direct effect on the density of compressible fluids such as gases. At higher pressures, gases become denser, which affects volumetric flow readings. For liquids, extreme pressure drops can cause cavitation, where vapor bubbles form and collapse, damaging both the meter and the process line.

How pressure affects the flowmeter

At very high pressures, mechanical components can deform slightly. This distortion can alter internal geometry and impact calibration. In differential pressure-based meters, changes in pressure can influence the pressure drop across the measurement device, affecting flow calculations.

Real-world example

In natural gas custody transfer, pipeline pressure can fluctuate due to supply and demand changes. Without compensation, these pressure changes can cause noticeable variations in measured flow volume, leading to disputes over billing.

Compensation strategies

- Pressure-compensated systems: Flow computers that take pressure into account can convert volumetric flow rates to standard conditions.

- Regular calibration: Calibrating under expected operating pressures ensures that any mechanical shifts are factored into the meter’s performance profile.

- Design for pressure range: Selecting meters built for the specific pressure range of the application reduces the risk of distortion and damage.

How viscosity changes flow profiles

Viscosity is the measure of a fluid’s resistance to flow. High-viscosity fluids flow more slowly and can shift from turbulent to laminar flow regimes. Low-viscosity fluids may flow faster and with less internal friction. These differences influence how fluid interacts with the flowmeter’s measuring elements.

For example, DEF (diesel exhaust fluid) is relatively low in viscosity compared to heavy crude oil. Turbine meters designed for DEF may not perform with the same accuracy when used for thick, high-viscosity fluids without recalibration.

How viscosity affects the flowmeter

In turbine meters, higher viscosity increases drag on the rotor, slowing it down and potentially underreporting flow. In positive displacement meters, high viscosity can improve sealing and accuracy, while low viscosity might lead to slip and under-measurement.

Compensation strategies

- Select the right meter type: Some flow meters, such as Coriolis meters, handle a wide viscosity range with minimal effect on accuracy.

- Use correction factors: Manufacturers often provide viscosity correction charts or software tools.

- Test under actual conditions: Verifying performance with the actual process fluid ensures the meter’s calibration matches real-world operation.

Combined variable effects

Why changes rarely occur in isolation

In most industrial environments, temperature, pressure and viscosity do not change independently. For example, in offshore oil production, extracted crude may experience simultaneous changes in pressure and temperature as it moves from the seabed to the surface, altering its viscosity as well.

Importance of multi-variable compensation

For the most accurate results, multi-variable transmitters or flow computers integrate readings from temperature, pressure and sometimes density sensors. This enables automatic compensation for all three variables at the same time, reducing error and improving reliability.

Best practices for accurate flow measurement

Select the right meter for the application

Choosing a meter type suited to the fluid properties and operating conditions is the first step toward accuracy. Turbine meters offer high precision in clean, low-viscosity fluids, while Coriolis or ultrasonic meters may be better for varying conditions.

Use integrated compensation systems

Pairing the flowmeter with temperature and pressure sensors connected to a flow computer allows for real-time compensation, bringing measurements back to standardized reference conditions.

Perform regular calibration and verification

Calibrating meters under actual operating conditions and verifying performance periodically ensures that changes in process variables are accounted for.

Work with the manufacturer

Consulting with the meter manufacturer can help determine the best configuration for specific process conditions and may reveal compensation features already available in your equipment.

Conclusion

Temperature, pressure and viscosity are three of the most significant process variables influencing flow measurement accuracy. Each can affect both the properties of the fluid or gas and the performance of the meter itself. In many real-world applications, these variables shift together, making integrated, multi-variable compensation essential.

By understanding how these factors interact and applying the right compensation strategies, facilities can improve measurement precision, reduce operational risks and ensure compliance with industry standards.

About the Author

Mark Weiss

Marketing Specialist, Turbines, Inc.

Mark Weiss is a marketing specialist at Turbines, Inc.