Labels or nameplates may seem like some of the more insignificant parts on complex gas and fluid handling equipment. However, these ID tags and warning plates, typically made of metal and bolted to the product, give the equipment a voice to say something specific and meaningful.

A flame detector with an etched nameplate details warning information, country of origin and other information. Courtesy of General Monitors

Nameplates inform, instruct and caution users about equipment. Information such as model number, date of manufacture, location and measurements (size, voltage, hertz, temperature) is commonly captured and organized on a nameplate or label (this article will use the two terms interchangeably). Technicians also use nameplates to ascertain when a product was installed and if there has been a change in the output of a part or machine. However, without the proper attention and preparation, this essential communication can break down for machinery built to control powerful, dangerous substances.

Metal & process matter

Especially in the pump and valve industry, crucial information can easily be lost if the optimal labeling material and process isn’t used. Nameplates are typically created by specialized suppliers who take on a consultative role, ensuring that the plates will withstand corrosive environments, prolonged exposure to oils, saltwater, high temperatures or other stressors they may encounter.

As equipment manufacturers adjust to the new economy, some entertain the notion of using label machines, milling and laser marking machines, stenciling, or simply no marking at all as cost-cutting alternatives to traditional nameplates. However, these measures are rife with uncertainty. Paint used to stencil may not have the correct chemical makeup to withstand its environment. Printed labels often lack adhesive strength for the variety of surfaces used in fluid handling equipment. Mechanical or laser marking may not achieve an adequate depth to be legible and resist erosion and wear.

A boiler pressure relief valve’s etched nameplate displays specs and a registration number. Courtesy of Watts Water Technologies

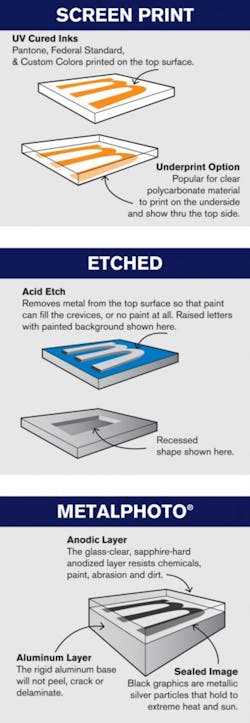

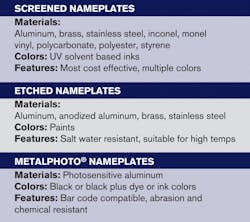

Nameplate production methods

Designers and product managers must ask: "Is the product properly labeled for possible hazards, warnings or other safety instructions?" The answer can have high stakes, particularly in applications such as mining and petroleum. Durable labeling for most industrial machines adds literally pennies to the final cost — an expense that could easily be outweighed by the legal fees and bad press from a single incident. Further, purchasers and operators of equipment create a safer work environment by purchasing machinery with clear labels made to last.

Label early

A natural inclination exists to finish a product and then put a label on it. However, considering the relevant regulations and labeling needs of a product early in the design and manufacturing process ensures they won’t interfere with the primary function of a machine or the timeline of delivery. No one wants to wait to ship a control valve worth tens of thousands of dollars because the labels were ordered late and not up to spec.

Because nameplates have been used to identify industrial equipment for more than a century, blueprints can sometimes include antiquated terminology. The industry also lacks consensus about what certain terms mean. This can be puzzling for manufacturers and creates delays if it is not addressed until the last minute.

Ultimately, the nameplates enable essential communication between the designer, manufacturer and end user for a range of gas and fluid handling equipment applications and stressors.

Joseph P. White is the business development leader at Willington Nameplate. He routinely works with GE, Flowserve, Honeywell, Watts, General Monitors and the rest of Willington Nameplate’s 1,500 customers to meet their labeling needs. He may be reached at [email protected] or 877-967-4743.