More than 100 million gallons of metalworking fluids (MWFs) are produced every year, exposing more than 1 million employees to these industrial fluids, according to the National Institute for Occupational Safety and Health (NIOSH). When these fluids are used in machining and other metalworking processes, they produce oil mist, a serious workplace hazard. For this reason, organizations using MWFs must understand the associated health risks to personnel and how to reduce these risks with collection systems.

Responsible employers must carefully control all metalworking processes that generate airborne mist contaminants. Without the proper precautions, the mist-laden air will be inhaled by machine operators and other employees, causing health problems. It will also land on tools and equipment, and accumulate on floors, causing a slipping hazard.

Oil mist machining

Categories of metalworking fluids

Two general categories of MWFs are used in machining processes: emulsion fluids and straight oils. Emulsion fluids are water-soluble and diluted with water up to their prescribed concentrations prior to use. They are used primarily as coolants in machining processes such as milling, drilling, tapping, turning and grinding that do not require high lubrication.

Emulsion fluids are generally a mixture of oil, lubricant and water plus additives such as emulsifiers, esters and sulfur compounds, rapeseed oil, polymeric alcohols (which inhibit foam), bacterial growth and corrosion. The oil or lubrication proportion is typically about 5 to 11 percent.

Straight oils are not water-soluble and are not mixed with water. These oils are used for metalworking processes that require the highest lubricating properties such as turning, drilling, milling, roughing, grinding, broaching, honing, rolling, deep-drawing and pressing.

Straight oils are used according to the manufacturer’s composition, which typically includes liquid hydrocarbon compounds (e.g., mineral oils or natural/synthetic oils) and additives (e.g., phosphorus, sulfur and chlorine compounds). The additives are used to prevent rust, reduce viscosity and reduce foam and oil mist. Oils that contain chlorine are extremely hazardous and require special attention.

Oil mist machining

MWF emissions and health risks

When MWFs are used in machining processes, the heat and mechanical processes produce the following three categories of emissions:

- Coolant-mist liquid aerosol emissions are formed from the cooling of condensation or mechanical processes.

- Coolant-vapor emissions are substances turned into a gaseous phase from a liquid phase through heating, i.e. hydrocarbons present in gas phase.

- Coolant-fume emissions are the finest solid particles in the air, which are generally formed during combustion processes.

Several adverse health effects are associated with exposure to MWF emissions, but the most severe are respiratory system ailments from inhaling aerosols and particles of less than 100 microns. Other serious reactions include pancreatic, colon, bladder and liver cancer, and tumors of the brain and respiratory organs. Contact with MWF emissions can irritate the digestive tract, skin, respiratory tracts and mucous membranes, and damage organs and nerves.

What the regulators have to say

Fortunately, laws, regulations and guidelines exist to define exposure limits and protect workers against many of these adverse health effects.

Occupational Safety & Health Administration (OSHA)

OSHA currently uses two air contaminant permissible exposure limits (PELs) that apply to MWFs:

- 5 milligrams per cubic meter (mg/m3) for an 8-hour, time-weighted average (TWA) for mineral oil mist

- 15 mg/m3 for an 8-hour TWA for Particulates Not Otherwise Classified (PNOC)

OSHA addresses MWF hazards in specific standards for general industry, shipyard employment and the construction industry. For general industry, the applicable standard is 29 CFR 1910, Subpart Z; Toxic and hazardous substances; 1910.1000, Air contaminants; Table Z-1, Limits for air contaminants.

National Institute for Occupational Safety and Health

NIOSH has set a much stricter recommended exposure limit (REL) for MWF aerosols of 0.4 mg/m3 for a 10-hour TWA for a 40-hour workweek concentration for thoracic particulate mass (defined as the fraction of inhaled particles capable of passing beyond the larynx during inhalation). NIOSH’s REL is intended to prevent or greatly reduce respiratory disorders causally associated with MWF exposure.

American Conference of Governmental Hygienists (ACGIH)

ACGIH has also set two threshold limit values (TLVs) for mineral oils:

- 5 mg/m3 for an 8-hour TWA

- 10 mg/m3 for a 15-minute, short-term exposure limit (STEL)

American Society for Testing and Materials (ASTM)

In 2003, ASTM published its International Metalworking Industry Standards: Environmental Quality and Safety, Fluid Performance and Condition Monitoring. This publication provides standard test methods, practices and guides for the proper selection and use of MWFs to ensure optimal performance and reduced worker health risk.

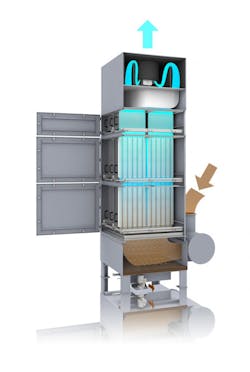

High-efficiency oil mist collector for pure lubricant oils

Types of oil mist collection equipment

In considering the appropriate mist collector to install, facility operators have several choices and should base their decisions on their respective process applications. Equipment used to capture MWF mists include:

Fiberglass V-bag mist collectors

Fiberglass V-bag mist collectors are the most commonly used and are offered by a wide range of manufacturers. These collectors use a first-stage Chevron metal filter, a second-stage aluminum mesh filter, a third-stage fiberglass V-bag with a 95 percent American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) efficiency rating and, often, a fourth-stage HEPA final filter.

It is important to note that ASHRAE’s rating system is used to measure the efficiency of dry particulate removal and has nothing to do with oil removal. Fiberglass V-bag style collectors can be used on straight oil and emulsion coolants. As the primary filter bags become saturated with fluid, these units lose efficiency and require regular filter changes to prevent emissions from escaping into the workplace. These collectors are effective on lighter-duty applications, but do not work as well for heavy-duty use and long production runs.

Centrifugal-type mist collectors

Centrifugal-type mist collectors use a rotating drum to spin out the oil, with an internal pad that serves as a final filter. If the unit collects too many metal chips, it can go out of balance and malfunction, causing a health hazard and requiring maintenance. Centrifugal collectors may be used for straight oil and emulsion coolants, and they work better in lighter-duty applications. If not properly vented, frequent opening of the door for parts change-out adds to the mist in the air.

Although centrifugal and V-bag collectors require relatively low initial investment, they are limited in terms of run time, filter service life and filtration efficiencies. Because straight oils and emulsion coolants have different properties and characteristics, facility operators might consider highly engineered collection systems specifically designed for use with straight oils or emulsion coolants.

High-efficiency mist collectors

High-efficiency mist collectors remove water-based coolants and emulsions. They are often built with two stages of long-life, coarse and fine filter demisters, followed by a final-stage HEPA filter with combined efficiencies of 99.9 percent on particles of 0.3 micron and larger. Units with integrated spraying systems can counteract emulsion gumming up in the system by maintaining the correct balance of water to oil. A spraying system can also clean the demister filters, which reduces maintenance and extends the life of the primary demister filter.

Tips for designing & using oil mist removal systems

- Because source capture collection systems contain mist at the machine, they are generally safer and more efficient for virtually any type of wet or dry collection system.

- Newer machines utilize better ductwork designs and air flow patterns to pull air out of the machine at the recommended cubic feet per minute air flow.

- Operators should maintain slightly negative pressure when machining to capture the fine mist without pulling chips, emulsion or oil into the collector.

- Equipping the oil or emulsion mist collector with a variable frequency drive lets operators reduce speed enough to contain the mist in the machine and avoid pulling mist and chips into the collector, which can shorten filter life.

- If compressed air is used to clean parts, make sure enough air is present to contain the mist in the cabinet to protect workers when changing out parts.

- Use a special hood or chip gate to separate out metal chips and preclean the oil because metal chips can drastically shorten filter life.

- Equip ductwork with proper fittings and seals that are specifically made for oil, and make sure the cabinet is leak-proof and will not seep oil.

- Request a filter emissions efficiency guarantee from the manufacturer to ensure the operation stays below required exposure limits.

- Minimum Quantity Lubrication (MQL) or near-dry machining requires a special prefilter in the oil mist collector to handle MQL and prevent ducts from becoming plugged.

References

- American Conference of Governmental Industrial Hygienists (ACGIH), 1330 Kemper Meadow Drive, Cincinnati, Ohio 45240, acgih.org.

- Mineral Oil, Excluding Metal Working Fluids: TLV(R) Chemical Substances, 7th Edition Documentation (2010).

- ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, 19428; astm.org.

- ASTM International Metalworking Industry Standards: Environmental Quality and Safety, Fluid Performance and Condition Monitoring (2003)

- ASTM Standard E 1687-98, Determining Carcinogenic Potential of Virgin Base Oils in Metalworking Fluids (1998)

- ASTM Standard E 1302-00, Standard Guide for Acute Animal Toxicity Testing of Water-Miscible Metalworking Fluids (2000)

- ASTM Standard E 1497-00, Standard Practice for Safe Use of Water-Miscible Metalworking Fluids (2000)

- ASTM E2889 – 12, Standard Practice for Control of Respiratory Hazards in the Metal Removal Fluid Environment (2012)

- National Institute for Occupational Safety and Health (NIOSH), 395 E St., SW, Patriots Plaza 1, Suite 9200, Washington, DC 20201; cdc.gov/niosh/:

- Criteria for a Recommended Standard: Occupational Exposure to Metalworking Fluids (1998).

- Preventing Health Hazards from Metal Working Fluids (2008)

- Occupational Safety & Health Administration (OSHA), 200 Constitution Ave., Washington, DC 20210; osha.gov:

- OSHA Permissible Exposure Limits – Annotated Tables (2013)

- OSHA 29 CFR 1910, Subpart Z; Toxic and hazardous substances; 1910.1000, Air contaminants; Table Z-1, Limits for air contaminants

- Metalworking Fluids: Safety and Health Best Practices Manual (2001)

Kevin Tucker is automotive market manager for Camfil APC.