Selecting the appropriate valve housing and valve seal material

To ensure a long-lasting valve, the correct valve type needs to be chosen carefully. Also, selecting the valve housing and valve seal material is a critical selection step. Improperly selecting the valve housing and valve seal material based on media and environment will affect valve performance (corrosion, seal, pressure capabilities, etc.) and shorten the operating life span. Taking the valve’s environment into consideration and knowing key media characteristics and material options will ensure the correct seal and housing material are chosen.

Application information for choosing valve housing and valve seal material

To select the appropriate material, gather all application information. From a media standpoint, the four main things to consider are temperature, corrosion possibility, wear characteristics and pressure. These will narrow down the material search before looking at environmental characteristics. Note if the valve is in a corrosive environment, if the material of the rest of the piping system will cause galvanic corrosion and its durability to withstand mechanical impacts.

Special circumstances

Not every application is straightforward, especially in the chemical industry. Some systems can run multiple different media through a valve. Maintenance intervals for cleaning, cleaning agents, temperature fluctuations external and internal to the valve, concentration of media and other factors can affect material selection. Also, the valve type can affect seal material (i.e., polytetrafluoroethylene [PTFE] is typically not used for low-pressure applications in solenoid valves but can be used for ball valves). If any uncertainty exists, it is important to discuss the application with a valve supplier to know the available options. Additionally, explore online resources to learn about the chemical resistance of certain materials.

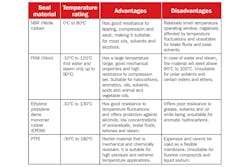

Table 1. Four main seal material options are available from valve suppliers.

Common valve seal material options

Table 1 presents the four main seal material options available from valve suppliers. For special applications (uncommon media, higher/lower concentrations, fluctuating/extreme temperatures, etc.), additional seal materials may be available, so consult with a valve supplier to find the correct seal based on performance, compatibility and price.

Common valve housing materials

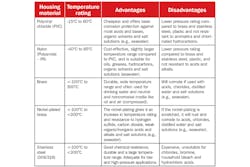

Table 2 discusses the five main housing material options available from valve suppliers. Consult with a valve supplier to find the correct housing based on performance, compatibility and price since additional housing materials may be available for special applications (uncommon media, higher/lower concentrations, fluctuating/extreme temperatures, etc.).

Table 2. Five main housing material options are available from valve suppliers.

Chemical applications

Since a plethora of chemical applications typically utilize more than one type of media, following are more common media types:

Alcohol (ethyl and methyl) — Besides as an alcoholic beverage, alcohols can also be used as a solvent, fuel source, perfume and cleaning supply.

- Ethyl and methyl — NBR is the most cost-effective seal solution for ethyl/methyl and together with a brass or stainless-steel housing, the valve will be suitable for the application.

- Other alcohols — For a single solution for almost all alcohols, PTFE can be used as the seal along with a brass or stainless-steel housing.

Glycol — Glycol’s main applications are for antifreeze, coolant, brake fluids and in the plastics industry as a precursor to polymers.

- Ethylene and propylene — Any of the four common seal materials will hold up in these applications, so it comes down to cost and availability along with a PVC or stainless-steel housing.

- Brake fluid — A valve with a nylon or stainless-steel housing along with an EPDM or PTFE seal will keep the valve operating with a media-like brake fluid.

A valve’s seals can consist of a flexible membrane (left) and O-ring (right).

Hydrocarbons — Hydrocarbons have an array of applications from natural gas and fuel to the plastic and medical industry.

- Petroleum — NBR is cost-effective and performs well with petroleum, but PTFE and FKM can also be used. From a housing perspective, it depends on the petroleum’s concentration/purity. If it is low, any of the four housing materials will suffice. Otherwise, stainless steel should be used.

Inorganic acids — Inorganic acids are widely used in the cleaning, pharmaceutical and agriculture industries.

- Nitric acid — Stainless steel 316 should be used as the housing material and depending on the concentration different seals should be used. For higher concentrations, PTFE; otherwise, FKM can be used.

- Sulfuric, hydrochloric and phosphoric acid — FKM, EPDM and PTFE can be used as a sealing material for these applications; however, if the sulfuric acid has a high concentration typically EPDM is not used. PVC or stainless steel have good performance and can be used as a housing material.

A typical solenoid valve housing

Organic acid — Organic acids are found throughout the food industry but are also used in pharmaceutical production and during the manufacturing of other organic chemicals.

- Carboxylic, sulfonic and phenol acids — PTFE is resistant to all three of these organic acids; however, FKM and EPDM can be used with a select few. From a housing perspective, PVC or stainless steel will hold up to these organic acids.

Acetone — Acetone is capable of dissolving fats, resins and cellulose esters, so it is used during the manufacturing of artificial fibers and as a chemical intermediate in the pharmaceutical industry. EPDM and nylon can be used on a select few acetones; however, valves are commonly specified with PTFE seals and stainless steal housings for these applications.

Chlorine — Chlorine is typically used to treat water and during the production of dyes, antiseptics, medicines and paper products. As a pure liquid, stainless steel housings need to be used. In other purity and forms, PVC should be used. PTFE should be used as a seal for all chlorine types.

Cost versus performance when choosing valve housing and valve seal material

Since valves are crucial components to any fluid control application, their performance and associated costs should be considered. Numerous types of chemicals, concentrations, forms and reactions need to be taken into consideration one by one. If the valve material cannot perform, it will cause system downtime, maintenance and valve replacement, leading to money loss. Taking the time to thoroughly understand the media, environment and valve material options is essential to ensure the system stays up and running. Share any concerns with a valve supplier.

Charles Kolstad is the marketing manager for Tameson, an e-commerce distributor that supplies valves and other fluid control products for businesses and private customers throughout Europe. Visit tameson.co.uk for more information.