Flow Control presents 2019 Innovation Awards honorees

Flow Control’s annual Innovation Awards program recognizes the latest innovations and technology breakthroughs in the fluid handling industry. For 20 years, the program has accepted nominations from companies that submit their solutions, and the honorees are determined by a reader voting process.

We would like to thank everyone who participated in the awards program by nominating or voting. And, congratulations to the honorees. We hope to see your solution nominated next year.

The following case studies demonstrate the technology solutions from the 2019 Innovation Awards winner and honorable mentions.Winner: IoTH800 Smart Valve

Ham-Let

Smart valve offers innovative solution for oil refinery’s analyzer sample collection

In the oil industry, a refinery can process more than 100 barrels of crude oil per day, so its maintenance and instrumentation departments constantly look to leverage technology that will increase the accuracy of its sample collection process. An accurate sample collection time stamp that matches closely to the process analyzer system’s predefined sample time will ensure that the overall system is correctly compensated based on results of the analyzer system.

The challenge

Currently, the analyzer sample collection is done manually and daily at a predefined time generated by the analyzer. However, operators must cover tens, or possibly hundreds, of sampling points at the predefined time stamp with minimum time deviation. This is prone to human error, as operators must complete the sample taken at the exact predefined time, and actual sample collection time often does not match the analyzer predefined sample times. As a result, the refining process is interrupted, yielding sub-optimal results. This translates to refinery yield losses, which has a direct monetary impact. In addition, an overcompensated refining process will also cost unnecessary stress to the system, resulting in higher maintenance costs.

Oil refineries operate under atmosphere explosible environments (or ATEX — an EU directive) with explosive media such as diesel and kerosene. Thus, the proposed solution in this case study had to comply with EX requirements. Battery operation and multiple sensing abilities had to be supported to provide a full solution. Current tools and instrumentation may not meet all requirements; they are also oftentimes standalone and expensive and may not provide an end-to-end solution.

The solution

Ham-Let IoTH800L-WLS-EX IoT valve version meets all of the stringent requirements with the following features:

- Multiple sensing capabilities

- (temperature, pressure, humidity, vibration, acoustics)

- High accuracy 0.1% EX certified pressure sensors

- Battery operation with safety certified battery (UL1642 or IEC 62133)

- Long operating battery life, more than five years (based on two transmissions per day)

- Long-range wireless uplink connectivity using LoRa WAN 1.1

Integrating the IoTH800 simplifies the complexity of system monitoring and control, which results in reduced total cost of ownership.

The Ham-Let IoTH800L-WLS-EX was deployed at the sampling points, replacing traditional valves. It detects the pressure changes when the operator actuates the smart valve to collect the sample. There is no new process, procedure or system being introduced, so this eases integration and minimizes errors.

The exact sample collection time stamp is captured and sent to Ham-Let’s IIoT cloud platform, Ham-Let Smart Valve Management System (SVMS). Subsequently, these time stamps are used for correlation with data collected from the analyzer system. This eliminates inaccurate and erroneous compensation, which will affect production yield, to the system.Ham-Let Smart Valve Management System (SVMS) is a cloud-based IoT portal with multilayered security shield for network, system and user-level protection. It connects products, plants, systems and machines, enabling customers to harness the wealth of data with advanced analytics. Ham-Let SVMS works with all popular web browsers.

Results

Ham-Let’s IoT Smart Valves present a breakthrough in the process valves industry. The solutions enable online monitoring, control and management of various processes, which consequently allows immediate response for safety events. It also enables machine learning and optimization, machinery and equipment protection, device tracking and additional customer-tailored features. In this case study, it has been demonstrated how Ham-Let IoTH800L-WLS Smart Valve and Ham-Let SVMS can provide a secured end-to-end solution. This helps solve customer problems and increase revenue through better production yield due to an accurate analyzer system and lower total cost of ownership.

In addition to this major challenge, deploying IoTH800L-WLS is as simple as replacing an existing valve with a smart valve. It also adds safety features by monitoring any upstream leakage and high temperature. Moreover, it is battery operated with a long wireless range of over 1.5 km, enabling IoTH800L-WLS valves to be deployed in sparsely located points with difficult accessibility.

Honorable Mention: Proline Prowirl F 200

Endress+Hauser

Steam quality increases efficiency and plant availability

Many industries use large quantities of steam, either for heating, cleaning or as an energy resource. Steam is the most used source of energy in industry. Thus, it is important to know the steam conditions and its quality.When discussing steam, one must first understand the three types of steam: saturated, superheated and wet steam. Saturated steam is the state where all the water has evaporated, and only a gaseous form remains. Superheated steam is the result of additional heating of saturated steam at a fixed pressure and elevated temperature. Wet steam is a two-phase state consisting of both water and steam, which is a result of fluctuating pressure and temperature that causes the liquid to condense.

There are serious consequences associated with wet steam, such as low efficiency of energy transmission, hazardous water hammer or heavy corrosions from the dissolved salts in the water. When determining which type of steam is present, the dryness fraction of the steam must be evaluated. Dryness fraction is used to quantify the amount of water present in steam.

As mentioned, saturated steam occurs when all the water has evaporated, which means the dryness fraction 1.0 or a steam quality of 100%. Saturated steam provides the most energetically efficient transfer of heat energy, as it is the most common type of steam. If the dryness fraction of the steam cannot be determined, it is impossible to accurately measure the amount of energy it contains.

For example, wet steam at 145 psi absolute and 355.8°F with a dryness fraction of 1% has a heat content of only 8.66 Btu/lbs., whereas with a dryness fraction of 100%, it has 866.43 Btu/lbs., which is dramatically different. In many applications in the process industry, pressure and temperature are often inconsistent and have large fluctuations. If such effects are not compensated, this can lead to massive measurement errors and thus a loss of energy and money when measuring compressible fluids such as gas and steam.

Endress+Hauser’s Prowirl F 200 vortex flowmeter can detect wet steam and even measure the dryness fraction of steam. This information can be used to compensate both mass flow and energy flow, thus dramatically reducing any measurement uncertainty.

At a steady flow rate and stable process conditions, the volume flow in a dry steam application will result in a stable vortex signal over time. If liquid water droplets are present, however, this will result in variations of the vortex signal, i.e., the droplets superimpose a second signal that influences the signal’s Kurtosis, which is analyzed by the Prowirl F 200. The Kurtosis is used for measuring the dryness fraction and detecting wet steam. In addition to the dryness fraction measurement, the Prowirl F 200 is also available with pressure and temperature compensation. This provides accurate measurement even in the case of unknown superheating occurring because of pressure-reducing valves.

Honorable Mention: ST80 Thermal Mass Flow Meter

Fluid Components International (FCI)

Thermal flow metering technology reduces maintenance for boiler air feed

A major, local engineering services company in Thailand was contacted by its customer to recommend, provide and install a new alternative flowmeter solution for a boiler’s combustion air feed. The customer was using a differential pressure flow device, which required constant, unplanned maintenance to unclog its orifices to keep it operating. Besides the dust and ash particles in the flow stream, the installation was further challenged by the high temperature, preheated air measurement, a 3-meter diameter pipe with a flat flow profile and a deep layer of insulation surrounding the pipe.The engineering services company contacted FCI’s local sales/service partner to recommend an alternative flowmeter solution. FCI’s new Model ST80 thermal mass air/gas flow meter was recommended and installed.

The ST80’s flow element design and capabilities were critical to the success of the installation and the application. The flow element was specified with FCI’s "high-temperature" flow sensor — capable of measuring in applications up to 454°C (850°F) — and with an application-optimized, heavy-duty open thermowells sensing head to ensure a nonclogging, no-maintenance sensor in the flow stream. Furthermore, the insertion-style flow element’s probe length was easily extended to reach through the pipe insulation.The installation of the flow element was elevated, and the ambient temperature around it was high, so remote mounting of the transmitter was also recommended. The sensor-mounted IP67-rated enclosure has no sensitive electronics embedded and is simply a junction box to attach sensor wires to the remote cable run. The ST80’s transmitter enclosure, also IP67-rated, houses all of the electronics, and it was remotely mounted 3 meters away, at eye level, where it could be easily accessed and the flowmeter’s data easily read on its digital LCD display with graphical capability by the operators.

FCI further optimized the application and installation by calibrating the ST80 to its specific measuring conditions. Using FCI’s high-temperature flow stand, FCI is able to flow high temperature air at the installation’s pressure conditions over the application’s flow rate and using a flat flow profile. Additionally, the ST80 meter was calibrated with an extended temperature compensation routine to ensure high accuracy and repeatability over a wide variation in temperatures.

The ST80 was installed successfully in the application, correctly the first time. It has been operating flawlessly and without any maintenance since its installation nearly one year ago. The user is pleased with the overall performance and the cost savings achieved by its no-maintenance thermal flow metering technology and FCI’s sensor design.

Honorable Mention: Micro Motion 4200 2-wire Coriolis Flow Meter

Emerson

Two-wire Coriolis meter meets a critical need at a major chemical plant

One of the largest chemical producers in North America — with facilities built in the late 1940s — struggled with legacy two-wire equipment that they needed to replace. They recently purchased Emerson’s Micro Motion 4200 2-wire Coriolis Flow Meter for use at one of their plants, and it was installed in mid-August. The new meter was intended as a replacement and upgrade to a particularly troublesome piece of legacy equipment.The 4200 replaced a differential pressure meter with impulse lines that had a history of plugging and causing wildly inaccurate readings. The new meter is located in the same place as the old meter: 20 feet high, with no scaffolding in place, and is part of a column used in solvent distillation. The meter measures the distillate sent back to the column as reflux. The application ensures a cleaner distillate in the column, which increases efficiency.

When the existing differential pressure meter became clogged, it could take technicians days to fully clear it. Alternatively, the process would have to be stopped to replace the meter, which meant lost production time and revenue. But even before a process upset caused by a clogged meter occurred, there would be inaccurate readings, which caused overuse or underuse of materials.It took the customer some time to determine the best option available as a replacement for this troublesome meter. They even considered a four-wire Coriolis meter, but a quick calculation showed that installing an additional two wires out to the meter would add approximately $25,000 in material costs alone and would pose safety risks associated with elevated work to route new wiring.

The customer was pleased to learn of the new 4200 meter, as it meant they could benefit from the accuracy and reliability of Coriolis technology for that particular application. With no moving parts that can wear out, no impulse lines and no need for additional wiring, it met their needs.

They installed the meter in a vertical, flow-up orientation, and it is self-draining so there will be no more clogging. The remote transmitter allows operators to quickly check the reflux flow rate, easily access the transmitter configuration and run diagnostics.

Initial reports from the customer are that they are seeing a dramatic improvement in accuracy and reliability, which means increased efficiency for the distillation column. They anticipate that the meter will prove a cost-effective investment long-term.

Honorable Mention: VorCone Meter

VorTek Instruments

Steam quality metering optimizes enhanced oil recovery (EOR) process control

Saturated steam flows are common throughout industry. To control and maintain optimum efficiency of a saturated steam process, it is necessary to know the steam’s quality and flow rate. However, saturated steam flow of a quality "x" less than 100% is two-phase flow, and two-phase flow metering is notoriously challenging. Using standard single-phase gas meters with such saturated steam flows produces steam flow prediction biases and does not produce a steam quality measurement. Furthermore, the few available steam quality measurement systems tend to operate over limited high-quality ranges (e.g., x is greater than 80%) only. VorTek Instruments’ VorCone Meter measures both steam quality and total mass flow across a wide range of quality.The VorCone Meter is a fully integrated hybrid vortex and cone flowmeter. These two dissimilar metering principles complement each other, giving far more information than either standalone meter. In saturated steam service, the VorCone Meter measures steam quality and total mass flow rate.

Heavy oil is a term that indicates highly viscous oil. This high viscosity inhibits the oil’s extraction from reservoirs. As such, the enhanced oil recovery (EOR) technique of injecting saturated steam to increase the oil’s temperature, thereby reducing its viscosity and making it easier to extract, is widely used. However, it is important to control the steam flow rate and quality. Too high a quality makes the process inefficient, i.e., more heat is supplied than necessary. Too high a steam quality can also cause scaling of the pipes. On the other hand, too low a steam quality means not enough heat is being supplied, and the process is sub-optimal. Optimizing the process requires measurement and control of the steam quality.The steam quality desired at oil pad injection sites is typically about 60% to 70%. Because existing steam quality instruments are usually for higher quality ranges (e.g., x is greater than 80%), they are not well-suited to this application. However, VorCone meters can operate where x quality is greater than 40% and have been proven to do so with service in heavy oil field applications.

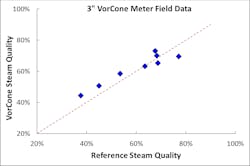

A 3-inch VorCone Meter was installed at a heavy oil field. This VorCone Meter’s quality measurement follows the quality as it is varied by the operator across a 40% to 80% range. The chart in Figure 1 shows results when this meter was connected to a portable reference system. This VorCone Meter uses the measured quality with a saturated steam flow correction to also meter the steam flow rate.

A 4-inch VorCone Meter was also installed at the outlet of a heavy oil field boiler. Whereas the operator traditionally had no independent boiler quality setting confirmation, this VorCone meter confirms a quality of 73%, closely matching the boiler nominal setting of 75%. The VorCone Meter gives the field operator a different level of control over their production process than previously achievable, assuring optimal process control and maximum efficiency of production.

Saturated steam VorCone meters are now considered for diverse applications such as EOR, pharmaceutical, tire factories and district heating systems, among others.