Tank Overfill ‘Levels of Concern’ and Recommended Actions

Many tank inventory operators have begun adopting the recommended practices set out in the American Petroleum Institute’s API RP 2350 fourth edition – which features safety measures to prevent tank overfill hazards. A key recommendation of API RP 2350 is the development of Levels of Concern, or LOCs, for each tank in an inventory.

RELATED: Key Factors to Consider When Assessing Tank Overfill Risk

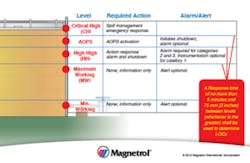

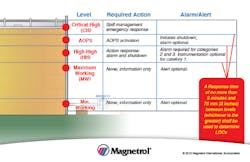

Simply put, LOCs are calculated product levels in the tank, upon which all alarm and alert positions and response times are based. Careful calculation of tank LOCs ensures the success of an overfill prevention system that complies with the API recommended practices. The API 2350 guidelines define five LOCs, starting from the top of the tank:

-

Critical High (CH) Level: The CH level is key to establishing other LOCs. CH is the highest level in the tank that product can reach without detrimental impacts, such as overflow or tank damage.

-

Automated Overfill Prevention System (AOPS) Level: The AOPS level is an optional emergency action alarm level necessary on tanks equipped with AOPS. It must be set sufficiently below the CH level to enable automatic termination of a receipt before the CH level is reached.

-

High-High (HH) Level: The HH tank level is an emergency action alarm level set sufficiently below the CH level to enable termination of product transfer before the CH level is reached.

-

Maximum Working (MW) Level: Another optional level set to the highest product level to which the tank may be routinely filled during normal operation.

-

Minimum Working Level.

For each LOC, the guidelines specify required actions, including necessary alarms, alerts and response times. For example, at the CH level, spill management emergency response is activated, with an allowable response time of no less than 5 minutes or 75 mm (whichever is greater), based on the prior level. The graphic below helps illustrate LOC definitions.

Download Magnetrol's API RP 2350 Readiness Kit.

This post originally appeared on Magnetrol International's blog, which can be found at levelandflowsolutions.magnetrol.com/blog/.