Ethernet Control for Motion Applications to More than Triple By 2016

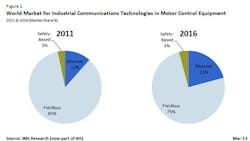

The use of Ethernet control for motor drives and motion controllers will more than triple to 2016 from 1.8 million new connected nodes in 2011, according to a new study from IMS Research, now part of IHS Inc. The compound annual growth rate (CAGR) for new motor Ethernet control nodes is projected to be the highest across the whole industrial space at nearly 30 percent.

“Ethernet, particularly certain industrial variants, is very well suited to drive and motion control applications,” IHS analyst Tom Moore said in a prepared statement. “The growing number of Ethernet protocols, which are high-speed, deterministic, and low jitter, mean its application has never been easier. Some of the most suited protocols are forecast annual growth rates exceeding 30 percent to 2016.”

RELATED: Ethernet Will Outpace Fieldbus in Industrial Automation Sector, Study Shows

Networking, however, isn’t just about the technology or protocols available; it is about the equipment itself, IHS says. Nodes, the connections to the higher network, are set to increase and part of this is being driven by an increasing number of ports per device. This has an added effect to the adoption growth of networking technologies. “The increase in node count has come about for several reasons,” Moore said. “More and more products are being released with the ability to daisy-chain, requiring at least two ports.”

IHS says Ethernet control is certainly making headway in the industrial space and its projected adoption growth is set to outstrip that of fieldbus technologies in almost all applications. “It is forecast that in 10 to 15 years Ethernet will have replaced fieldbus as the mainstream networking technology for motor control products.” says Moore, “This can only be good for the unification and simplification of networking solutions; driving down costs and increasing up-time”.

“The World Market for Industrial Ethernet and Fieldbus Technologies – 2013 Edition” is now available from IHS. This includes extensive analysis of industrial Ethernet control and fieldbus technologies used in motor control, process and control, and discrete control.