The term hazardous location once meant a place within a petrochemical or some other equally volatile plant. Today, hazardous manufacturing processes include coatings, adhesives, and flammable liquids in parts-cleaning tanks and dry-cleaning plants. Even food processing and other agricultural-related industries are becoming familiar with hazardous designations by the nature of the processes involved, such as grain elevators or flour and feed mills. Textile mills and any plant that creates sawdust also fall into the hazardous category.

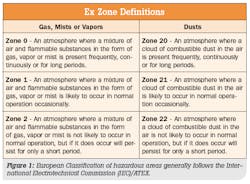

Selecting equipment that may be used in such locations requires an understanding of how hazards are classified. NEMA, Underwriters’ Laboratories, and the National Fire Protection Association have categorized hazardous environments by classes with divisions similar to European ATEX zones. See Figure 1.

Hazardous-Area ClassificationsRELATED: How Safe Are Your Systems? In the pursuit of process safety, knowhow and expertise are key

Two other safety aspects are commonly included in the classification of devices for use in hazardous areas—gas groupings and temperature classification. The gas grouping takes account of the maximum amount of energy that can be released under operating or fault conditions. Temperature classification is concerned with the maximum temperature, which can be attained by the external surface of the device.

Temperature Classification: Gas-air mixtures can be ignited by contact with a hot surface. Consequently all electrical equipment used in hazardous atmospheres must be classified according to its maximum surface temperature. Figure 3 shows the ignition temperature to be taken into consideration in Europe (EEC) and the United States (NEC) for the gases and vapors stipulated there.

All temperature classifications, unless otherwise specified, are assessed with reference to a maximum ambient temperature of 40 C (104 F). If the equipment is used in a temperature higher than this, then its temperature classification should be reassessed.

Gas or Apparatus Grouping: The same gas groupings are used for flameproof and intrinsically safe equipment, and tables are available showing the equipment classification, which can be used with particular groups of gases. Figure 4 gives some examples with the IEC and North American classifications. Gas groups E, F, and G (not shown) are concerned with hazards associated with the presence of dust.

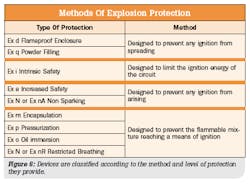

The overall term used in Europe covering all methods of protection is explosion-proof, and the symbol Ex is used. In the United States, engineers tend to use the term explosion-proof as being synonymous with the European term flameproof, and this often causes confusion. The methods for explosion protection are outlined in Figure 6.

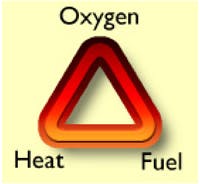

Methods for Safe Control: Understanding design methods for operating equipment in hazardous areas starts with the combustion triangle. Fuel, oxygen, and a source of ignition (spark or temperature) must be present at the same time (and in the necessary proportions) for combustion to occur (Figure 7).

One approach to creating a safe environment for hazardous areas is confinement; isolating the area reduces the possibility of accidents. Isolation involves removing or confining any possible element that could create a spark and ignite an explosion. There are three common methods of providing safety within a hazardous location, categorized by the power technology used: (1) pneumatic; (2) explosion-proof; and (3) intrinsically safe systems.

Pneumatic Systems: Pneumatic systems are, by their nature, a safe means of control because they are powered by air. Pneumatic systems are generally clean and easy to service, but the number of control operations performed by pneumatic sequencers is limited. This can be augmented by an electro pneumatic interface that enables pneumatics to be controlled by a Programmable Logic Controller.

The drawbacks to pneumatic systems are in distance and reaction times; where installations are spread over a wide area, the slow reaction time of pneumatic systems increases control reaction time. The length of control circuits in a total pneumatic system must be limited for the control cycle time to remain short.

Explosion-Proof Housings…NEMA Classifications: Explosion-proof housings provide a simple means to adapt electric and electromechanical and electro-pneumatic controls to hazardous locations. Explosion-proof housings are designed to withstand the explosion of a mixture inside the enclosure and to prevent the spread of the flame to the outside. These enclosures are effective, especially for interrupting high currents to motors using limit switches. However, this method lacks flexibility in the use of sensing techniques because of the size of the devices. In addition to the space required for explosion-proof devices, material and labor costs for installation and service may be high. See NEMA Classifications in Figure 8.

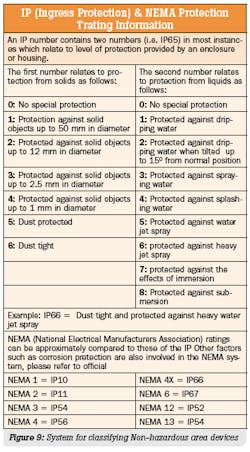

Ingress Protection (IP): IP ratings specify the environmental protection the enclosure provides. This is not a system of hazardous-area classification (Figure 9).

The IP rating normally has two numbers:

- Protection from solid objects or materials

- Protection from liquids (water)

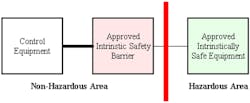

Intrinsic Safety: Intrinsic safety implies that there is insufficient electric energy in a circuit to ignite the most readily flammable mixture of a gas and air. As mentioned in relation to classification, the energy can appear as a spark resulting from its sudden release or in thermal form from the temperature rise of a surface. The equipment design must consider fault conditions as well as normal operation. See the schematic in Figure 10.

According to the National Electrical Code, “Intrinsically safe equipment and wiring shall not be capable of releasing sufficient electrical or thermal energy under normal or abnormal conditions to cause ignition of a specific flammable or combustible atmosphere mixture in its most easily ignitable concentration.”

There is a fundamental difference between intrinsic safety and the other equipment application techniques. None of the others aims at preventing release of energy at a dangerous level. Instead, they avoid possible effects in a number of ways:

- Ensuring that when a spark occurs, it is prevented from reaching an explosive mixture

- Ensuring that any explosion is contained

- Reducing the hazard by diluting the gas mixturel

- Protecting against excessive temperature or spark

Intrinsic safety, on the other hand, deals with the root cause and ensures that there is insufficient energy available, whatever happens, to cause an explosion. It is, therefore, considered by some to be the safest and most technically elegant approach. It has a number of practical advantages, offering compact design, reliability, low cost, simple installation, and the possibility (not available with flameproof equipment) of on-line maintenance, if required. The principal disadvantage is the relatively low amount of power available, although this has been largely overcome by a growing range of specially designed components and equipment. For all practical purposes, intrinsic safety is the only safe technique suitable for Zone 0 and is often the preferred approach for Zone 1 (Division 1).

There are two standards on intrinsic safety in IEC countries:

- “ia” being the higher standard where safety is maintained with up to two faults

- “ib” where safety is maintained with up to one fault

Equipment certified to “ib” standards is generally acceptable in all zones except Zone 0, and “ia” equipment is suitable for use in all zones. In the United States there is only one standard, requiring safety up to two component faults.

Intrinsically Safe Elements In an Automated Valve Package

Pneumatic actuators for process valve automation are well suited for low-power or intrinsically safe system integration. Where electric motors or other high-power devices do not directly interface with today’s computer-controlled systems, pneumatic actuators when properly sized and fitted with compatible control accessories can satisfy a variety of computer-direct process control requirements. When used in an intrinsically safe system, pneumatic actuator control accessories must be connected to a properly selected and approved barrier.

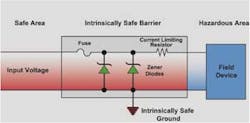

What are intrinsic safety barriers? Intrinsic safety barriers are current- and voltage-limiting assemblies that are designed and constructed to requirements as described by ANSI/UL 913 (formerly NFPA 493) in the United States and CSA 22.2 number 157M in Canada.

When operating conditions are abnormal, the intrinsic safety barriers circuit is designed to divert excessive current to ground. This diversion is accomplished by the Zener diodes, while current limiting is provided by a resistor. If voltage higher than the maximum allowed by the safety barrier is applied across the barrier, the Zener diode would then conduct that excess current to ground. Should current continue to increase, the fuse will open the circuit arresting current flow altogether (Figure 11).

Advantages of low power: All other methods of protection—e.g., pressurization, use of explosion-proof enclosures, or oil filling—rely on the maintenance of a physical barrier between the explosive atmosphere and the electric circuit. Physical barriers, if breached at any single point no longer provide the appropriate level of protection. In contrast, intrinsically safe elements provide inherent protection by restricting the energy at its source and as a result offer some advantages that include:

Economy. Enclosures are lighter, less cumbersome, and economical. Costly screwed conduits can be replaced by ordinary wiring. Thermocouples, resistors, switches, and other non-energy storing field equipment can be constructed to ordinary (weatherproof) specifications.

Live maintenance. It is not necessary to cut power before calibrating or otherwise adjusting field equipment. Glanded or magnetically coupled controls through flameproof housings are not needed.

Reliability. The system remains safe if seals fail, cables are severed, or the covers of enclosures or conduit boxes are improperly replaced. Switches do not require long, thin flame-retarding air gaps, which are prone to corrosion and seizure.

Safety. Personnel cannot be harmed by the low voltages used in intrinsically safe circuits.

There are three common electric components that are used with pneumatic valve actuators: the solenoid valve, limit switch, and transducer (or electro-pneumatic positioner). Each of these devices is manufactured in a version that allows them to be classified as low-power and are therefore appropriate elements for use in an intrinsically safe system.

It must be emphasized that a component with an intrinsically safe approval will only be safe either when installed within the terms of the approval documents and of the relevant codes of practice or when the system configuration has been given prior expert approval.

Typically, the cost of an intrinsically safe component is comparable or slightly higher than the standard explosion-proof device. When one considers that explosion-proof fittings and conduits are no longer needed, on the average the installed system may be less costly for an intrinsically safe devices. Operating costs are also lower as power consumption is negligible, and an intrinsically safe system can be serviced in hazardous areas while the power is on, something that cannot be done with standard explosion-proof devices.

Finally, when an intrinsically safe system is installed correctly, it is always explosion-proof. When standard explosion-proof housings are damaged or there are errors in installation that allow a flame path to develop, the system is no longer explosion-proof. Some insurance companies have rewarded companies who install intrinsically safe systems by charging them lower premiums.

Wayne Ulanski is the president of SVF Flow Controls, Inc. in Santa Fe Springs, Calif. For more than 20 years he has provided technical advice, design assistance, and training materials to support the process control marketplace. He has authored two books, one of which remains a staple in the industry—Valve and Actuator Technology. He was instrumental in establishing a major actuator company in the U.S. and is currently leading a technology-based initiative at SVF that will include a complete family of automation and controls devices. Mr. Ulanski can be reached at [email protected].