Saint-Gobain’s OmniSeal Anti-Blowout Seal Qualified for Rocket Engine Check Valves

May 19, 2014

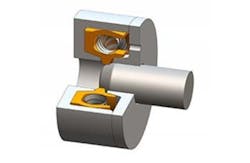

Saint-Gobain Seals’ OmniSeal spring-energized, anti-blowout seal has been qualified as a static seal in rocket engine check valves for the aerospace industry. Anti-blowout seals are used in check valves to retain pressurized fluid on the high pressure side, while preventing blowout of the seal from the housing. Under high pressure, as well as rapid change of pressure across the seal surface, retaining the seal in its housing is very challenging. The purpose of the OmniSeal anti-blowout seal used in the check valve of the rocket engine is to seal pressurized gas and liquefied gas from temperatures below -300 F (-184 C) up to 122 F (50 C). The seal is proofed for pressure close to 3,000 PSI (207 bar). Saint-Gobain Seals’ anti-blowout seal, derived from its OmniSeal 103A configuration, consists of a polymeric jacket with a spring-energizer. The seals in the check valve application are capable of operating from cryogenic temperatures up to 575 F (302 C), and can withstand pressure up to 6,000 PSI (414 bar).

Sponsored Content