(a.k.a. "The Pump Guy")

Almost everyone I know does something to decrease energy consumption, like consolidating numerous daily trips in the family car, additional home insulation, or installing energy-efficient lighting. Every little bit helps to conserve energy and ensure an existence for future generations.

Many people want to do more. But, the economics of paying double the price for an electric automobile with limited facilities to recharge the batteries seems a stretch. How can “Joe the Plumber” justify trading the family sedan for something that looks like a roller skate on steroids? It’s a difficult decision and hard to justify.

I work as a pump consultant and contract mentor. I normally look at sick pumps that vibrate, cavitate, or eat bearings. But recently, I’ve been meeting with managers who want to reduce operating costs.

Twenty-five years ago, managers were ordered to produce more with less people. This meant mechanization, more machines, assembly-line robots, servo-motors, more electricity, and hydraulic power drives.

Now those same managers are charged with producing more at lower energy cost. There is no one left to downsize. The robots eat more and more energy and they never attend the “team building” meetings. Maybe we can downsize some slacker robots?

OK, that’s enough sarcasm for one “Pump Guy” article. The best way to reduce operating costs is to improve efficiency. This will be reflected in the monthly electric bill.

Someone said a decade ago that industrial pumps consume 20–25 percent of the world’s available energy. Assuming this is relatively accurate, let’s consider efficiency in industrial pumps.

With most industrial process pumps, the efficiency is determined by two factors. One factor is the pump’s duty coordinates (head and flow) on the performance curve. I frequently write about the operator’s contribution to reliability in controlling the pump to best efficiency duty coordinates.

The other factor is the gap (free space) between the OD of the impeller wear ring and the ID of the casing wear ring. The gap is set at the pump factory. The gap tends to open with time and erosion. The pump loses about 2 percent efficiency for every 0.001-inch excess gap beyond the original factory setting.

Wear rings are inexpensive compared to other pump consumables like mechanical seals, couplings, bearings and impellers. It is a good idea to replace the wear rings every time the pump comes into the shop.

I’m not an accountant, although I took a couple of accounting courses at university and I do the accounting for my company. To a corporate accountant, a pump isn’t a pump—it is an asset.

The energy to power the asset (pump) is a “variable operating cost.” It is variable because it only exists when the pump is operating. Accountants always want to know, “How much does this asset (pump) cost us each year in energy to operate?”

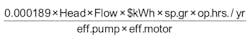

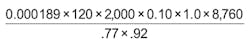

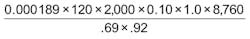

Here is the answer for pumps with electric motors. It is a simple formula called the Operating (Electricity) Cost per Year =After six months of service, the pump is disassembled and measured for erosion. The gap in the wear bands had opened an additional 0.004” beyond the original factory setting. The pump lost 8 percent efficiency through the gap. The pump is now 69 percent efficient. The electricity expense for this pump increases to $62,595.

The 0.004” additional wear in the wear bands is costing an additional $6,503 per year in energy for this one pump. The wear bands for this pump might cost $80 to purchase and maybe three to five hours of time and labor for a back pull-out process pump.

You can use this same “Yearly Electricity Cost” formula for other issues regarding process pumps and electric motors. Maybe you are comparing two pumps for purchase. One pump is cheaper and less efficient; the other pump costs more and has elevated efficiency. This formula will give you the information you need to purchase the correct pump with the savings in variable operating costs (electricity).

You can use this same formula to justify operator training and adequate instrumentation on process pumps. It is a well-known fact that most pumps (assets) languish at low (25–40 percent) efficiency because the pumps have no gauges indicating head and flow, and the operators never received training to interpret the gauges with performance curves.

Let’s work another creative example: Let’s say you will lay some pipe for a modification to a cooling tower at work (or maybe you want to pipe the plumbing under your hunting cabin in the woods). You need 1,000 feet of Schedule 40 carbon steel pipe. Projected flow is 600 GPM at 16 hours per day (5,840-hrs/yr.). You want to use 8” diameter pipe. The purchasing agent wants to buy 4” pipe because it is cheaper to purchase.

Sadly, too many purchasing agents only have the “selling price” to help them make decisions. Let’s quantify the energy with the formula:

A resistance chart for carbon steel (Schedule 40) pipe reveals:

- The friction loss (Hf) at 600 GPM for 1,000 ft. of 4” diameter pipe is 186’.

- The friction loss (Hf) at 600 GPM for 1,000 ft. of 8” diameter pipe is 6’.

- You will purchase a pump for this application that is about 80 percent efficient.

- The proposed electric motor is about 93 percent efficient.

- Electricity in your state is $0.12/kWh.

You can say to the purchasing agent, “I understand that 4” diameter pipe costs less to purchase than 8” pipe. However, the energy to overcome the friction losses through 4” pipe will cost the company $19,868 each year in electricity. The energy to overcome the friction losses through the 8” pipe is only $641 each year in electricity.”

You go on to say, “I calculate the larger diameter pipe will pay for itself in energy from friction losses in about 26 months (or 42 months, or whatever). The cooling tower modification has a projected life of 20 years. After the 8” pipe has returned the investment in cost difference, the remaining 16 years will earn about $xx,xxx for the company in energy savings. After 20 years, the 4” pipe will actually cost the company $XXX,XXX in excess energy.”

How can the purchasing agent (or VP of Finance) say no to this proposal?

People, you could change the incandescent light bulbs to energy efficient lighting in every home in your entire neighborhood, and you won’t produce the savings that you could realize with one or two small pumps at work.

Learn to support your arguments and proposals with kilowatts and dollars. It’s the language of the bean counters. We’ll win the energy war and secure the future for our kids.

Or, you can write to your Congressperson! Maybe they’ll listen. Yeah right!

The next Flow Control/Pump Guy Seminar will be in Indianapolis, Ind., June 16-18, 2015. Contact Matt Migliore [email protected] for details.

Larry Bachus, founder of pump services firm Bachus Company Inc., is a regular contributor to Flow Control magazine. He is a pump consultant, lecturer, and inventor based in Nashville, Tenn. Mr. Bachus is a retired member of ASME and lectures in both English and Spanish. He can be reached at [email protected].