Autonomous science: The future of chromatography applications

In chromatography applications, smarter systems, machine learning and ever-increasing amounts of data are creating new possibilities to automate, reduce unplanned downtime and predict maintenance schedules. This, in turn, widens the customer base to include a wider spectrum of professionals, not just specifically trained scientists. These developments are in part fueled by leaps in sensor technology that, for example, allow online liquid flow rate measurements down to single nanoliters per minute.

Artisan science

Early iterations of chromatography systems required their operators — typically a highly trained scientist in a high-tech research facility — to manually prepare each sample for the next experiment. While an analytical procedure or process can be as short as minutes or even seconds, typical sample preparation steps take hours to complete. This sample preparation depends on the specific compounds of interest and may include weighing, filtering, evaporation, liquid-liquid extraction and homogenization.

But the manual work was not yet done. Each of the painstakingly prepared samples then had to be loaded into the system, one by one, at just the right time. This required the operator to be dedicated to the system during the entire process.

Even after the experiments were finished, the work continued in the form of number crunching of the experimental results. The potential for optimization and automation was huge.

A new state of the art

Current systems are automated to much higher degrees and offer full workflow integrations ranging from sample preparation to data analysis and visualization. Automation systems can differ in their design, and they can range from systems to replicate and emulate manual methods to closed systems that do part of the sample preparation, for example, in a benchtop system. Whereas the latter automates specific processes to an optimal degree, the former can be more flexible. Robotic systems that mimic a typical manual process can be adapted to perform different steps to complete another process in a similar automated fashion.Versatile impact

This is, however, only the beginning. The high value of the test results of chromatography workflows and analytical instruments in general will cause their success to do nothing but increase. Current fields of interest include the food and beverage industry, where the results give insights into the safety of our nutrition. Given the ever-increasing demand for highly optimized and high-yield food production processes, every production batch will reach an ever-increasing number of consumers. Their health and safety thus depend on the safety and stability of the production processes.

Pharmaceutical products aim to help and heal the sick population, a group whose immune system is, in many cases, already compromised. For these patients in particular, the safety, security and reliability of controlled production processes is key. Analytical instruments and workflows are already used to control for these safety aspects, and with newer and more complex treatments becoming available, the demand for such workflows to be efficiently and seamlessly integrated into the production processes will increase further.

Already at the development stage of vaccines, for example, chromatography systems help identify the specific antibodies involved in fighting different diseases and thus enable fast production of specific compounds to combat the spread of potentially life-threatening epidemics.

Hidden championsWith the prevalence of such analytical systems only increasing in industry and research, the demand for and development of automated and stable processes for completing the workflows around the actual analysis will also increase.

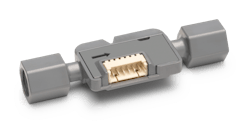

A large portion of these developments are enabled through smart sensor solutions. For example, Sensirion’s sensor solutions enable dispense validation, process control and optimization and failure mode detection in myriad applications. Whether an application requires the monitoring of environmental factors such as humidity and temperature, CO2 concentration or particulate matter or the precise measurement and control of liquid and gas flows, Sensirion’s fully calibrated and digital sensor technologies offer a reliable basis for process and workflow automation and control.

Dr. Moritz Kneipp is key account manager of Life Science, Diagnostics, and Analytical at Sensirion AG. Headquartered in Stäfa, Switzerland, Sensirion AG is a manufacturer of digital microsensors and systems. Its product range includes gas and liquid flow sensors, differential pressure sensors and environmental sensors for the measurement of humidity and temperature, volatile organic compounds (VOC), carbon dioxide (CO2) and particulate matter (PM2.5).