Thermal mass flowmeters (TMFMs) measure or monitor the mass flow of air, gas or a gas mixture in countless applications. Like any flowmeter technology, however, there are applications where they excel, and there are ones to avoid. Understanding how the meter deviates from other measurement technologies is important when considering this meter style. This article reviews the critical factors to consider when determining if a thermal mass flowmeter would effectively work in an application.

Thermal mass measurement versus other technologies

Understanding the difference between a thermal mass flowmeter and other measurement technologies is the first step in deciding if the TMFM is the correct device for an application. The primary difference between a TMFM and other technologies is that it directly measures mass flow versus volumetric flow based on heat transfer.

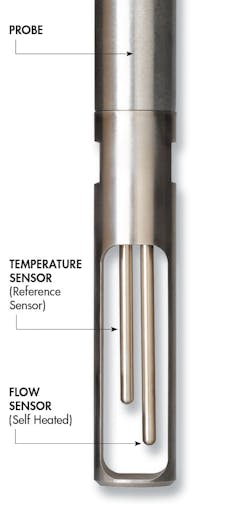

Gas is compressible. The gas volume changes under pressure and temperature fluctuations. For this reason, orifice plates, venturi meters and other Delta-P (differential pressure) devices, as well as turbine meters, rotary gas meters and vortex meters, require additional instruments to measure the temperature and pressure and then mathematically convert the volume to mass. A TMFM does not need separate temperature or pressure transmitters as it directly measures mass flow. (See Figure 1.)The Coriolis meter is another direct mass flowmeter. It is accurate and reliable, but expensive and costly to install. It is also challenged in low flow, low-pressure applications when there is pressure drop.

What is mass flow?

Mass flow is a gravimetric measurement of mass moving over time, expressed as pounds per hour, kilograms per day, grams per second or similar units. A thermal mass flowmeter is expressed as standard cubic feet per minute (SCFM) or normal cubic meters per hour (NCMH). Since these units of flow rate are standardized at specific temperatures and pressure, they resolve into mass flow units.

The flowmeter manufacturer specifies the “S” in SCFH; that is, it stipulates the standard reference conditions for pressure and temperature. For natural gas applications, the “S” is generally 60°F and 29.92 inches of mercury, while for air applications, the “S” usually is 70°F and 29.92 inches of mercury. One SCFM of a gas (or air) at the “S” conditions represents a specific mass flow rate because there is a known number of molecules in a cubic foot of a gas (or air) at “S.” For this reason, units of SCFM, SCFH, SCFD and NCMH are mass flow units.

Why is mass flow important?

In practicality, all medical, industrial, environmental and commercial flow rate or totalized flow applications require the mass flow rate.

- Medical oxygen flow rate

- Industrial batching or weighing applications

- Industrial processes involving chemical reactions

- Environmental applications, such as flare gas

- Combustion control on a boiler or furnace for efficient operation

- Tenant billing or sub-metering of natural gas

A thermal mass flowmeter provides mass flow directly. Therefore, there is no need for ancillary temperature or pressure measurement devices to convert to mass flow. In contrast, the previously mentioned technologies require extra transmitters, along with installation and wiring for these devices, and require calculations to convert from volumetric to mass flow.

9 benefits of thermal mass flowmeters

Here are nine beneficial features of thermal mass flowmeters.

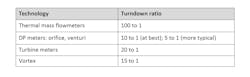

TMFMs have a high turndown ratio of at least 100 to 1, meaning that they accurately and repeatably measure a substantially greater range of flow rates over other flowmeter technologies. Additionally, on the differential pressure (DP) meter, the transmitter accuracy degrades at low differential pressures, affecting the meter’s accuracy. (See Table 1.)Importance of proper installation

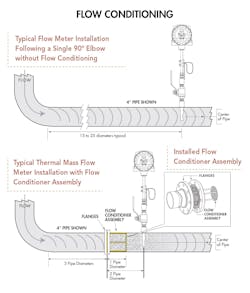

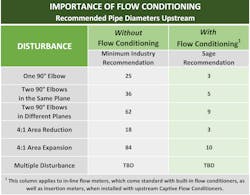

The location for a flowmeter installation is essential and often overlooked. Selecting a location solely based on ease of installation is often shortsighted. The end user should consider the location’s flow disturbances before choosing the position for a meter, especially in the case of an insertion-style thermal mass flowmeter. For this reason, give thoughtful consideration to determining the most suitable site. Ideally, a well-developed turbulent flow profile is required and achieved with an adequate upstream straight run. Otherwise, accuracy suffers.

Once the location is selected, identify the disturbances so the manufacturer can determine if flow conditioning is required, and if so, the flowmeter would be factory-calibrated with conditioning. Unfortunately, most piping does not have sufficient straight run, and flow disturbances arise because of fittings/couplings, expanders, reducers, valves, tees, headers, bends, filters, strainers, knockout drums, heat exchangers, regulators, flanges and elbows. Figure 3 shows how to approach some common upstream disturbances.

Selecting the proper meter and specifications

Selecting the correct flowmeter for an application is the only way to guarantee accuracy. Share the application requirements with the manufacturer when specifying any meter. The following items should be considered:

- Gas or gas mix

- Pipe size and schedule or pipe ID

- Insertion or inline style (NPT/flanges)

- Integral or remote

- Display (orientation) or blind

- Product configuration (general-purpose, explosion-proof)

- Flow response, temperature response, temperature compensation

- Approval requirements (Div 1, Div 2, CE, CSA)

- Accuracy requirements

- Standard outputs (4-20 mA of flow rate, pulsed outputs of consumption, temperature)

- Accessories (tags, software, special sensor material for corrosive gases)

- Parameters to display (flow, temperature, totalized flow)

- Communication outputs (Modbus, BACnet, HART)

- Expected full-scale flow rate (if pulse output, specify pulse rate)

- Standard operating temperature and pressure (include ranges)

- Mounting hardware (valve assemblies, flow conditioners)

- A photo or drawing of the installation (optional)

Wiring considerations

Thermal mass flowmeters require power to operate, and typical options are 115 VAC, 230 VAC or 24 VDC. Some manufacturers’ meters require up to 20 watts to operate, which can become problematic if the power available is 24 VDC. Other manufacturers' models require as little as 2.5 watts, offering the possibility of running multiple meters off of a single power supply. In any case, verify there is sufficient power available to meet requirements.

Keep in mind the following to assure that the thermal mass flowmeters and the systems have sufficient wiring:

- All TMFMs provide 4-20 mA output proportional to flow rate along with other standard or optional outputs.

- Optional outputs may include pulsed outputs of consumption, temperature and communication outputs such as Modbus, BACnet or HART.

- Consider requirements for a SCADA system, PLC or Building Management System.

- Is an isolated 4-20 mA output required? If so, is the meter required to externally or internally power the output?

- When using a remote-style meter, the manufacturer provides a transducer with the flow element as well as the remote transmitter. Some manufacturers provide the custom interconnecting cable; therefore, if additional length is needed, specify when ordering.

Applications to avoid

Thermal mass flowmeters measure most gases and gas mixes, including air, argon, biogas, butane, methane, carbon dioxide, digester gas, ethylene, flare gas, flue gas, landfill gas, nitrogen, natural gas, oxygen, propane and propylene.

As with any measurement technology, it has its strengths and limitations. Here are some challenging applications to avoid using TMFMs unless the user exercises the noted measures.

- There is an insufficient upstream straight run. An alternate location should be selected unless flow conditioning resolves the issue.

- If condensation develops in the gas stream, droplets may hit the sensors and create spikes, causing over-reporting. In an insertion-style TMFM, if the droplets originate from the pipe (rather than in an atomized gas stream), consider angling the probe. By mounting the probe at an angle (rather than vertical), the droplets drip from the probe, avoiding the sensor. This measure generally resolves the issue.

- Avoid using TMFMs in widely varying gas mixtures. All NIST traceable TMFMs need calibration with the actual gas or gas mix. If the mix changes significantly, like flare gas, the heat transfer changes, and errors occur. If the mixture uncertainty (the estimated variation) is identified in advance, the manufacturer can provide a mid-range calibration and the expected error for the extreme situations. When applying manufacturer-provided K-factors or by using manufacturer-provided software, known mixture changes oftentimes provide acceptable performance. This approach is typical for measuring biogas, and often, the reduced accuracy is acceptable.

- Avoid using TMFMs in high-temperature applications (where the gas temperature exceeds 450°F). The electronics of an integral meter may fail if heated above 150°F. One solution is using a remote-style configuration, where the electronics board resides in the transmitter, rather than in the probe or flow body enclosure. Note, however, that even with a remote style TMFM, when gas temperatures reach 500°F, the standard insulation degrades within the sensor. Unless a manufacturer provides a TMFM specifically constructed for extreme temperatures (usually limited to 850°F), avoid high-temperature applications.

- Avoid corrosive gases, such as chlorine, because it damages the 316 SS sensors. Some manufacturers offer Hastelloy alternatives. In such cases, direct calibration is not possible, and surrogate gas is needed. Consequently, accuracy may suffer.

- Hydrogen and helium require calibration under pressure. Unlike other gases, errors occur when the gas pressure changes. This application requires a reasonably stable pressure, and the flowmeter manufacturer needs to calibrate under pressure and, in the case of hydrogen, also contend with safety issues.

Conclusion

A thermal mass flowmeter has numerous advantages over other technologies for measuring the mass flow rate and consumption of gases. Featuring wide rangeability, pressure independence, extreme low-end sensitivity and ease of installation, they have become widely popular for countless commercial, industrial and environmental applications. Furthermore, by offering a variety of configurations and outputs, TMFMs provide the flexibility and economy to accommodate mostly any type of gas flow application.

To use a TMFM to its fullest potential, give thoughtful consideration to the installation location, the meter’s flow body and which features are best for the application.

Bob Steinberg is the founder, president and CEO of Sage Metering. He has over 40 years of instrumentation experience. Before forming Sage Metering in 2002, he managed thermal mass flowmeter sales at Kurz Instruments, Sierra Instruments, and Eldridge Products. While at Weston Instruments, he was a product marketing engineer. He has a BSEE and a BA from Rutgers University.

About the Author

Bob Steinberg

Bob Steinberg is the founder, president and CEO of Sage Metering. He has over 40 years of instrumentation experience. Before forming Sage Metering in 2002, he managed thermal mass flowmeter sales at Kurz Instruments, Sierra Instruments, and Eldridge Products. While at Weston Instruments, he was a product marketing engineer. He has a BSEE and a BA from Rutgers University.