The next generation of multiphase flow measurement

From the impact of COVID-19 to the digitalization of the modern oilfield, there can be no doubt that the oil and gas market is changing. For producers wanting to stay ahead of the curve, embracing advancements in automation and data-driven technology is essential. One key area of innovation taking place is multiphase flow measurement. With the oil and gas industry poised to exploit more challenging reservoirs, advances in flow measurement software architecture will ensure operators are supported with the reliable insights they need to ensure efficient and optimized production — even in the most demanding field conditions.

The go-to solution for multiphase flow measurement

In the past, operators most often targeted “straightforward” reservoirs with fewer geologic anomalies, resulting in more stable flow conditions. Typically, the flow profiles of these wells would sit in the so-called “sweet spot” of multiphase flow, which is 25% to 85% gas volume fraction (GVF). Multiphase flowmeters excel at analyzing within this range, providing accurate and reliable measurement. Today, however, oil and gas pioneers are able to tackle reservoirs they could only dream about even 10 years ago. Reservoirs that would have remained untouched previously are being developed now. Fortunately, multiphase flow measurement technology has evolved along with the industry, and it consistently proves itself up to the task.

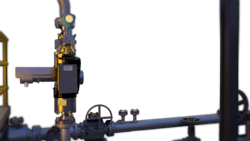

Multiphase flowmeters are a popular choice for the modern oilfield for many reasons. A flexible option that adapts to changing well conditions, these meters allow for the replacement of expensive and bulky legacy equipment. With a footprint that is up to four times smaller than older meters, producers save on space, weight and installation costs, while reducing the number of instruments required. Measurements taken directly from the wellhead that do not require moving parts decrease downtime and maintenance requirements. With a number of meter sizes and replaceable venturi sleeves, one meter can last the entire lifetime of a well, as well as cutting down on capital investments at the well pad.

The industrial internet of things (IIoT) revolution has arrived in oil and gas, leading to digital improvements in these metering solutions, as well. Remote connectivity grants operators full access to their well data from anywhere in the world, as well as access to remote supplier expertise. That means no more traveling all the way out to each site if an issue is detected or waiting until there is a production issue downstream, since much can be achieved remotely. Fewer hours on the road also dramatically improves safety for workers. Pairing this remote access with real-time data analytics enables insight into production that allows for faster process improvements and remarkable optimization efforts across the field. Instantaneous awareness of changes in production or detection of layer buildup, for example, means that discovering optimum choke settings and injection rates is quicker, easier and more informed. When optimizing an entire field, real-time data like this saves countless hours and resources.

Because it is a fully agile solution, multiphase flowmeters are capable of adapting with these advancements in technology, making them virtually future-proof. New modules can be developed and added to tackle unique and emerging applications. The latest developments in embedded software mean even better performance in rapidly fluctuating flow profiles, all in a simple and easy-to-use package.

A lot can happen in a tenth of a second

When wells produce at a smooth and steady pace, flow measurement devices can give operators the insight they need with lower data resolution. Steady streams of oil and gas mixtures can be relatively consistent from one interval to the next. However, significantly more demanding conditions mean varied and dynamic flow regimes that require higher resolution data to truly understand what is happening in the pipework. The ability to capture data in intervals of a tenth of a second establishes a much more accurate representation of the flow composition and rates.

Advances in multiphase embedded software have seen pressure changes of 5 bar in less than a second. Slugs exploding through the pipework, shifts from predominately liquid to predominately gas and back again, and minuscule quantities of water bursting through — can all occur in fractions of a second.

These changes correspond to a change in all of the reference densities used in flow calculations, affecting the final rate calculations. If it happens enough over time, without extremely high-resolution measurement, these dramatic swings could jeopardize an entire operation.

Producers may not even realize these fluctuations are happening in their pipelines, so this real-time knowledge is extremely valuable. When it is understood what detailed events are occurring, operators can achieve better performance and accuracy with their measurement devices.

Better performance leads to more confidence in production data while also being able to utilize this information to optimize well performance.

How software is changing the game

Now that it is possible to capture this level of data, a software solution is needed that is able to draw actionable information from it. This is where advanced, adaptive module selection comes into play. The latest software platform for multiphase flowmeters is now able to synchronize sensor signals, run multiple calculation modules with parallel computation, self-verify each module’s suitability, and then automatically select the best-suited measurement modules at any given moment. From this, a producer can derive the most accurate data possible, no matter how unstable or demanding multiphase flow conditions are.

This software platform has already been tested in multiple sites with significant results. An operator in the Marcellus basin in North America adopted automation enhancements in its multiphase flowmeters. Because the Marcellus application is challenging, with 90% to 99.9% GVF, typically a reference test separator was used to perform in-line calibration on the meter during installation. Despite the challenging nature of this gas asset, once measurements were initially aligned, the multiphase flowmeter was perfectly repeatable. However, when its software was upgraded with the new rapidly adaptive capabilities, all previous adjustments to reference instrumentation became superfluous. The meter performed well and matched reference instrumentation straight out of the box.

In the Eagle Ford and Denver-Julesburg basins in North America, layer detection and correction features that are available in the software platform have led to significant cost savings related to maintenance and cleaning. Now the multiphase flowmeters automatically compensate for both conductive and insulating layers, wax or scale buildup, which results in maintaining high-quality, reliable measurement with reduced cleaning cycles.

An embedded PVT engine

Previously, multiphase flowmeter suppliers have relied on PVT (pressure, volume and temperature) tables to support conversion of actual conditions to standard. These tables were prepared in a separate software and then uploaded to the flow computer. New adaptive measurement functionality now includes an embedded PVT engine within the flow computer of the multiphase flowmeter, which has two equations of state and two property libraries available. Operators can apply their own equations of state to the engine. The PVT engine inside the flow computer allows for more robust and seamless calculations as flow conditions change. Using separate software to calculate PVT variables is no longer necessary, which eliminates additional meter configuration changes. These streamlined calculations are no longer limited by the edges of PVT tables but can handle the true range of these dynamic multiphase environments.

Additional capabilities are possible for multistage flashing, allowing operators to compare data with test and bulk separators at different pressures and temperatures and to verify the metering process. Advanced PVT capability makes gas lift integration easier than ever, too. The engine can take a hydrocarbon ratio of produced gas to lift gas and blend the compositions, so the meter uses a correct hydrocarbon composition and PVT data for its calculations — all within the automated functionality of the flowmeter.

The future of flow in software innovation

Demands on flow metering instrumentation are only going to increase over time. The future of multiphase flowmeter technology lies in digitalization and software innovations that push past these barriers and make possible what used to be impossible. The latest leaps ahead in embedded software in multiphase flowmeters are enabling new levels of reliability, functionality and efficiency in formidable reservoirs worldwide.

Kelda Dinsdale is a customer adoption manager for Emerson’s Roxar Flow Measurement product line. She has held various roles across a number of departments since she joined the company in 2008. For the past 10 years, Dinsdale has been working predominantly to support the Roxar 2600 Multiphase Flow Meter in commercial and product management positions.

Michael Samaha is a product specialist for Emerson’s Roxar multiphase flow meters in North America. He has a Bachelor of Science in electrical engineering from Louisiana Tech University and has been working with multiphase metering in Emerson for the past 16 years.

About the Author

Kelda Dinsdale

Customer Adoption Manager for Emerson’s Roxar Flow Measurement product line

Kelda Dinsdale is a Customer Adoption Manager for Emerson’s Roxar Flow Measurement product line. She has held various roles across a number of departments since she joined the company in 2008. For the past 10 years she has been working predominantly to support the Roxar 2600 Multiphase Flow Meter in commercial and product management positions.

Michael Samaha

product specialist for Emerson’s Roxar multiphase flow meters in North America

Michael Samaha is a product specialist for Emerson’s Roxar multiphase flow meters in North America. He has a Bachelor of Science degree in electrical engineering from Louisiana Tech University and has been working with multiphase metering in Emerson for the past 16 years.