Case Study: Wireless tank gauging system improves accuracy for bulk storage terminal business

An industry leader in the handling and storage of bulk liquid products throughout North America replaced an obsolete hardwired tank gauging system with a wireless solution to increase the accuracy of tank content level monitoring to less than 1 mm and temperature readings to ±0.9°F. In addition to meeting OIML custody transfer requirements, the improved accuracy is important for inventory control as well as overflow and runout prevention.

The bulk storage terminal business stores a variety of products including petroleum, biofuels, commodity/specialty chemicals and vegetable/tropical oil products in tanks located in terminals throughout the country. At one terminal, 50 of 230 tanks were retrofitted with the wireless gauging system, while 21 of the 80 tanks at another terminal represented new wireless installations.

Products supplied

- Nivelco Multi-Temperature Transmitter (Thermopoint)

- VEGA PULS64 Radar Transmitter

- SignalFire Sentinel HART Wireless Node with HC Solar panel (self- contained Class 1, Division 1 intrinsically safe solar power system)

- SignalFire Gateway Stick with Ethernet interface module

- SignalFire Pressure Scout (intrinsically safe wireless pressure sensor and radio)

- SignalFire Sentinel Digital Node

The challenge

A current wired and powered tank gauging system with a wireless option for communications was costly and had limitations in communicating over long distances. The network required repeaters between tanks that increased installation complexity and costs. The system also did not easily support the addition of new tanks to the network due to its complicated configuration requirements.

The solution

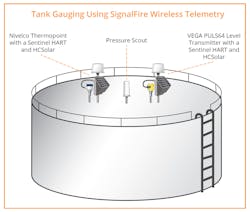

In operation, SignalFire Sentinel HART nodes with a solar power system collect and transmit data from level and temperature sensors for transmission to a Gateway via a HART signal. A custom-fabricated mounting bracket assembly supports the nodes and solar panel for easier installation on the tanks.

A Modbus TCP Ethernet module transfers information from the SignalFire wireless mesh network to an Ethernet network where it is received by an Inductive Automation Ignition HMI via a Kepware driver that passes it to a tank inventory management software. With data collected from all measurement instruments on the tanks through the SignalFire wireless telemetry system, the software gives operators a complete tank content overview, providing inventory and custody transfer functions with API net volume calculation. It also offers HART configuration and calibration, alarm handling and reporting, and proof-testing from a control room.

Using a proprietary 900 MHz radio network system for communications with devices, the wireless gauging system provides reliable data transmission over long ranges under different weather conditions to send information such as tank levels or temperatures to a control system up to 3 miles away and, in some cases, a further distance due to mesh technology inherently built into the wireless technology. Radio-based telemetry systems using communication networks based on a 2.4 GHz frequency band can only travel approximately 700 feet and would require a network of repeaters to communicate the equal distance of SignalFire’s 900 MHz solution.

System components

New smart temperature sensors installed in various points throughout tanks provide individual spot or averaged temperature data. Up to 15 smart temperature sensors are integrated within one stainless steel, flexible cable probe. Mounted atop the storage vessel, the temperature sensors offer precision temperature correction in tank gauging systems involved in the transfer of product by level (not metering) measurement.

The plug-and-play capability of the radar and temperature sensors make it easy to configure, install and fine-tune the system with minimum programming or configuration effort while offering a pre-engineering solution to achieve the custody transfer requirements.

The temperature component of the system provides a measurement for every specified foot to provide a value for more accurate volume calculation. As the walls and floor of the tank expand and contract by temperature, the actual volume varies by location.

A Pressure Scout Intrinsically-Safe Wireless Pressure Sensor serves as a pressure indicator on a nitrogen pressure regulator for tank blanketing on some tanks while a Sentinel Digital Node provides a manual valve open-close indication of a chemical injection system for other tanks.

Implementation

After a successful test of the SignalFire wireless tank gauging system on 25 tanks at one site, the company added them to 21 tanks at another site and then went back to the original site to upgrade 25 more tanks.

Compared to another wireless solution that required the level and temperatures to be hardwired to the tank, the SignalFire solution that powers the sensors by a solar source offered a more viable solution at a lower cost.

By implementing a wireless solution, the bulk storage terminal company can add tanks to the network at its own pace around its operations as it does not require conduit or other mechanical equipment for installation. Wherever tank level and temperature data are needed from remotely located storage or process tanks, the SignalFire Wireless Gauging System provides a cost-effective, time-saving, wireless, clean and energy-sustainable solar-powered solution over traditional, hard-wired field topology. The terminal company will implement the wireless tank gauging system in other terminals across the country in the future.