Case Study: Level control for a high throughput catalytic pilot plant

In the oil and gas industry, maximizing efficiency has become increasingly important to avoid waste and minimize environmental impact. While technical advances in the past decade have resulted in significant improvements, research continues to develop methods to increase efficiency even more.

High throughput experiments for catalyst research offer an effective means for the industry to test and understand a wide range of variables. The multi-channel pilot plants designed for this purpose must be reliable, precise and versatile to perform the series of tasks required of them. Process control of pressure, temperature, flow rate and level are key elements in these systems.

Zeton, a global leader in pilot plant design and fabrication, recently designed a pilot plant with 12 catalytic reactors to perform high throughput experiments for vegetable oil, animal fat, diesel and vacuum gas oil hydroprocessing. Sustainable Aviation Fuel (SAF) was a particular focus of the intended research.

Zeton’s customer for the project (IFPEN) requested an upgrade to the pilot plant design to improve automation of the separation process. Steady-state level control during separation results in more accurate analysis of the liquid and gas samples. Due to the pilot plant’s extremely wide flow rate ranges combined with wide viscosity ranges, system designers found that traditional methods of level control were not adequate. Switching to a dome-loaded direct-sealing back pressure regulator (BPR) to perform level control provided much improved performance.

The challenge

Each of the 12 reactors in the pilot plant has a distinct low pressure stripping column downstream of the reactor to perform gas/liquid separation just prior to sampling. Having stable pressure in the column allows for certain volatile species to remain in the liquid sample rather than flash to the gas stream. Pressure disruptions may cause flashing and compromise the quality of the sample analysis. Maintaining a steady state level control in the separator vessel avoids the pressure disruptions.

In many similar pilot plants, this stripper column level is satisfactorily controlled with a metering valve in series or with an on/off valve using a high and low threshold for opening and closing; however, when flow rate, pressure or viscosity changes are involved, the process becomes more complicated, often requiring human intervention to adjust the opening of the valve. This particular pilot plant system includes both an extremely wide flow rate range as well as a wide viscosity range, thus requiring an operator’s time and attention.

The solution

To address the problem, Zeton collaborated with Pressure Control Solutions, a fluid control specialty company that works extensively with research scientists and industries in Northern and Western Europe. The team incorporated a dome-loaded direct-sealing back pressure regulator from Equilibar to make the system more autonomous in adapting to changes in flow rate and viscosity.

This type of controller uses multiple orifices sealed by a flexible diaphragm, allowing it to control across a wide range of flow rates. The diaphragm is nearly frictionless in its movement and offers extreme sensitivity, responding to changes within milliseconds. As flow requirements change, the diaphragm moves a few millimeters to open and close over none, some, or all of the orifices, providing instantaneous and frictionless control.

It is dome-loaded by a pilot regulator setting the setpoint on top of the controller. The pilot setpoint pressure may be set with an electronic pilot regulator, which makes the controller well-suited for automation. Unlike conventional level control devices, the multiple orifice regulator is able to provide accurate level control despite fluctuations in flow rate or variations in viscosity.

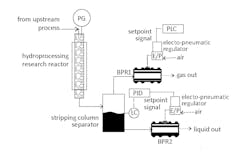

The stripping column is held under pressure with a direct-sealing back pressure regulator, BPR1. The electro-pneumatic pilot regulator automates the pressure control to a setpoint signal from a PLC in the pilot plant. The liquid level in the stripping column is controlled by a second direct-sealing back pressure regulator, BPR2.

BPR2 control is automated through a proportional-integral-derivative (PID) feedback loop with a level sensor. The PID signals an electro-pneumatic pilot regulator to set the air pressure on the dome. BPR2 opens and closes to keep a 1:1 ratio of the air pressure on its dome to the liquid pressure at its inlet.

Advantages

The primary advantages of using a direct-sealing diaphragm regulator for this scenario is that it can operate across a 10,000:1 valve coefficient (Cv) range. By combining this with closed-loop control based on feedback from the level controller, the system is able to handle the wide ranges of flow and viscosity required by the application.

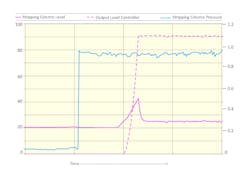

The chart in Figure 3 is a sample from the stripping column data. The initial filling of the separator is shown.

The column level (solid pink line) rises as the reaction progresses. The output (dotted pink line) of the PID rises in response, increasing the pressure on the dome of the BPR. This restricts the flow just enough to hold the level constant by matching the liquid out-flow. The PID is able to continuously adjust the dome pressure of the BPR to keep the liquid level under control, even without the aid of a flow sensor. The gas pressure (blue) remains relatively consistent throughout as it is controlled by a gas phase dome-loaded BPR.

The extreme sensitivity of the regulator controls level accurately, making changes instantaneously despite dramatic changes in flow rate, viscosity and pressure. While an operator could also manually adjust a needle valve in combination with an on-off valve to address these changes, the regulator provides a faster, more accurate response and avoids the problem of restarting the automation algorithm.

An additional problem with manual adjustment is that any slight delay in operator reaction could result in a system restart if the liquid level falls too low. The pilot plant performs best when the level control device is able to work in automatic mode with optimized P&ID parameters. The dome-loaded direct-sealing back pressure regulator allows for that optimum performance.

Jeff Jennings, PE, is founder and president of Equilibar, a technology company that designs and manufactures direct-sealing back pressure regulators for complex applications in research and industry. Jennings has more than 30 years of engineering experience in a variety of industries including chemical, nuclear and materials. He holds several international patents and continues to do active research in the field of fluid control.

Armand Bergsma is the founder and director of Pressure Control Solutions in The Netherlands. He has more than 20 years of experience developing high-value systems to address flow and pressure control challenges. Bergsma is known for his innovative approach in combining back pressure regulators with specifically designed electronic reference pressure controllers and other high-performing products.

About the Author

Jeff Jennings

Jeff Jennings, PE, is founder and president of Equilibar, an engineering company that specializes in precision fluid control for challenging applications around the world. Jennings has more than 30 years of engineering experience including 16 years with The DuPont Company. He holds several international patents and continues active research in the field of fluid controls. He may be reached at [email protected].