One of the first steps for digital transformation in industrial plants and facilities is automating manual data-gathering processes, an activity often referred to as digitization. This has typically been accomplished using wired and wireless in-plant networks to gather data from process sensors. These networks work well for monitoring critical parameters but can be costly for gathering data from other less critical or far-flung points of measurement.

The LoRaWAN wireless standard is often a better choice when adding sensors where data only needs to be gathered at relatively long intervals, such as once an hour, or when sensor data must be transmitted over fairly long distances up to 1 kilometer (km). LoRaWAN is a type of long-range, wide-area network, allowing internet of things (IoT) devices to communicate over extended distances with minimal sensor battery usage.

This article first looks at the leading reasons to undertake digital transformation and then examines how wireless networks can enable these efforts.

Digital transformation rationale

Maintaining the status quo is no longer acceptable in the process industries due to building pressure from a number of areas, such as:

- More stringent health, safety and environmental regulations are forcing facilities to digitize so they can maintain their operating licenses.

- Changing industry demographics are creating leadership, succession and competency challenges — along with different worker needs.

- Proliferation of data and data-driven organizations is compressing time frames for decision-making and introducing new digital competitors.

- Technological innovation and digitization are causing disruption and forcing consideration of new operating models.

- Rise of shareholder involvement is driving demand for financial stewardship and asset optimization.

These and other factors are driving the need for digital transformation — the process of digitizing and acting upon data. When implemented correctly, this can transform a company by reducing safety incidents, eliminating unplanned outages and enabling nimble response to market demands. These benefits can be realized by a rigorous adherence to operating plans implemented by a motivated and informed workforce.

An example is using big data analytics to improve condition monitoring of critical plant assets such as compressors, heat exchangers and pumps. In the past, the data required for monitoring the condition of these types of assets was gathered by technicians using pen and paper. Once gathered, this data was manually entered into a condition monitoring and asset management software platform, where it was manually analyzed by experts to reveal areas of improvement.

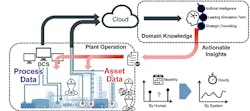

But there is a better way through digital transformation. Figure 1 depicts current best practices using wireless monitoring to automatically gather data at much more frequent intervals than practical with manual readings and data entry. This cuts costs dramatically compared to manual methods, while improving safety by limiting the need for personnel to spend time in the field.Both process and asset data are transmitted via the cloud to an advanced asset performance management platform. The asset data can be transmitted using LoRaWAN wireless, bypassing the process control system. Subject matter experts (SMEs) can then interact dynamically with all this data to improve asset uptime, drive better performance and cut maintenance costs by predicting failures prior to occurrence. SME interaction is enhanced by artificial intelligence and simulation technologies built into the asset performance management platform and by assistance from third-party experts via strategic consulting agreements.

These types of improvements address many of the aforementioned challenges, and it all starts with data collection, which is made easier with wireless networks and instrumentation.

Long-range wireless

As mentioned, many industrial plants and facilities already have wireless instrument networks in place for collecting asset data. These wireless instruments and networks work well in the types of applications where data must be collected rather frequently, typically every 10 seconds or less, and within a relatively small area.

But a long-range, wide-area network is often a better choice when lengthening distances at ranges over 500 meters line-of-sight or when lower sensor and network costs are desired.

Figure 2 depicts this type of network installed in an industrial plant — with a LoRaWAN compatible sensor installed on a rotating asset (shown on left in Figure 2) and connected to a LoRaWAN gateway at a distance up to 1 km.

The sensor shown can be easily installed and relocated because it attaches magnetically to the asset. A long battery life of about four years at update rates of once per hour keeps maintenance expenses in check. The sensor is intrinsically safe, so it can be safely installed in hazardous locations often found in process plants, and it has a wide operating temperature range of -20˚C to 80˚C. These types of sensors are much less expensive than a typical wireless instrument, opening up new applications for monitoring, such as the following examples.

Application examples

Vibration measurements for 200 items of rotating equipment installed in a chemical plant were being manually recorded by a third-party firm at a cost of $48,000 per year. The inspection results were not digitized and only represented a snapshot of data at a point in time, severely limiting the plant’s use of the information.

Wireless vibration sensors were installed and connected to a LoRaWAN network, with data sent to an asset performance management system. This digital transformation eliminated the annual third-party fees and enabled real-time equipment status checks, along with automated alerts sent to plant personnel.

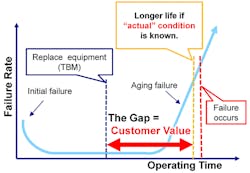

In a second application, a refinery was replacing a critical piece of equipment once every five years per the vendor’s guidelines at a cost of $100,000 per replacement. By installing wireless monitoring, refinery personnel were able to examine actual operating conditions and extend the equipment life to nine years, resulting in a costs savings of 45% (see Figure 3).

A third application cut maintenance costs by $100,000 per year through the installation of wireless temperature sensors on 300 fermenters at a pharmaceutical plant. Each sensor was configured to alarm if trouble was detected, with vibration sensors and accompanying analysis planned for the future.

In a fourth application, LoRaWAN compatible vibration monitoring sensors were installed on the gearbox and generator for each of 70 wind turbines spread over a wide area. Remote analysis of integrated vibration and operating data (power generation, wind direction, rotation, weather, etc.) is being used to extend the life of each wind turbine.

In another chemical industry example, LoRaWAN compatible vibration monitoring sensors were installed to monitor the acceleration of pumps to detect signs of abnormality prior to failure. Sensor data is used to indicate the abnormal rise in acceleration peak value, which is a leading precursor of ball bearing failure.

Conclusion

Each of these examples show how wireless monitoring can be used to implement digital transformation.

Figure 4 depicts a roadmap to digitization success through a five-step process, starting with readiness and ending with value sustainment. The fourth step, operational execution, is where wireless monitoring comes into play as a best practice for data collection. Once data is collected, it can then be analyzed and acted upon to create and sustain value.

Simon Rogers is the head of the Advanced Solutions division at Yokogawa Electric Corporation. He has more than 30 years of global experience in the use of information and control technology to improve the safety, sustainability and efficiency of the process industries. Rogers holds a Bachelor of Engineering (BEng) in chemical engineering from Imperial College, London.