Improving carbon dioxide capture efficiency of amine processes using advanced measurement technologies

Key Highlights

- Accurate measurement of flow, pressure, temperature, and chemical composition is essential for optimizing CO₂ capture efficiency and process safety.

- Advanced instrumentation like Coriolis flowmeters, ultrasonic flowmeters, and WirelessHART sensors enable real-time monitoring and reduce maintenance costs.

- Monitoring corrosion potential through wall thickness sensors helps prevent equipment failure and ensures operational safety.

- Real-time analysis of amine solvent quality and CO₂ levels improves process control, solvent longevity, and overall system performance.

- Effective management of absorption and desorption parameters, including pressure and temperature, is critical for maximizing CO₂ removal and energy efficiency.

Efforts to reduce emissions of carbon dioxide (CO2) are expanding around the world. For example, captured CO2 is diverted for direct utilization in various chemical processes, or processed for sequestration/storage, ensuring it does not contribute to climate change.

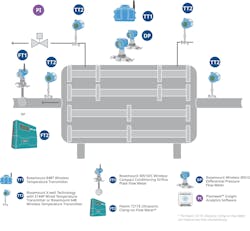

In this article, we will concentrate on the most common capture process: liquid amine absorption (Figure 1), showing ways to make this process more effective and efficient through strategic use of process instrumentation.

The amine process runs continuously and involves chemical absorption, where a gas stream containing CO₂ is placed in contact with a liquid solvent containing amines. CO₂ is absorbed by the amine solution, allowing CO₂ lean gas to exit at the top. CO₂ rich amine is sent to a desorber to strip CO₂ and recycle the lean amine back into the process.

Applying instrumentation

As with any process, the primary objective is to optimize energy and performance, while maintaining safety. Accurate measurements for timely actions are critical in meeting these objectives. In an amine treating process, there are several critical measurements that need to be monitored and controlled to ensure efficient CO₂ capture, process safety and solvent longevity. These include flow, pressure, temperature and chemical composition.

Mass balance — Carbon capture must be regarded as an extension of the main process producing CO₂ rich gas because the two must respond in tandem to any operational changes. Amine flow must match both overall gas flow and CO2 concentration to optimize removal efficiency, while minimizing solvent consumption and costs. The optimal measurement in this case is direct mass, for example with a Micro Motion Coriolis Mass Flowmeter (Figure 2). This provides data to perform mass balance across the entire system. In addition to ensuring the correct ratio of solvent to gas, it allows for effective measurement of CO₂ in each of its phases: liquid, gas and supercritical for pipeline transport.

Heat exchangers — Heat exchanger performance, especially the lean-rich amine heat exchanger, and accurate steam measurement around the stripper, can significantly contribute to reducing energy consumption, thereby improving process efficiency. Minimizing energy consumption and maintenance costs start with equipping heat exchangers with the right measurement technologies since there are many distributed throughout the unit. A 2% restriction in throughput due to fouling can waste up to 10% of total energy input, making efficient monitoring essential. Non-intrusive devices — such as Flexim FLUXUS Ultrasonic Flowmeters, Rosemount X-Well Technology and WirelessHART-enabled instruments (Figure 3) — simplify installation, while optimizing performance.

Steam management — Accurate steam supply and control is required to heat amine solvent and efficiently extract CO₂. Using a compensated flow measurement, either DP or Vortex (Figure 4), provides significantly better measurement accuracy, allowing for better mass and energy balance, reducing process variability.

Monitoring corrosion — The corrosiveness of amines, which are known to be aggressive towards carbon steel, and CO2, due to its ability to create carbonic acid, are areas of concern for maintenance departments. Corrosion potential increases with increasing amine concentration and CO₂ loading. Wall thickness measurement sensors (Figure 5) can be installed throughout a unit on pipe and vessel walls to monitor metal thickness continuously. Data from these sensors can be transmitted via WirelessHART to an automation or asset management host system so engineers can make decisions in real-time, with the data historized for analysis. Host systems can also trigger an alarm when wall thickness has reached a safety threshold.

Amine solvent quality and CO₂ integrity — Real-time monitoring of amine solvent composition and CO₂ is critical for determining solvent degradation and process efficiency (Figure 6). Over time, amines can degrade due to oxidation, thermal breakdown or reaction with impurities.

When monitoring amine composition, manual sampling can introduce safety risks and process inefficiencies. By monitoring amine density or concentration, along with CO2 concentration, in near real-time, operators gain an accurate view of amine condition and carbon dioxide capture rates. This technology improves operational efficiency and safety.

Absorption and desorption — Pressure and temperature play an important role in both absorption and desorption (Figure 7). As absorption is especially impacted by the gas partial pressure, measurement of this variable is critical in managing absorption efficiency. Temperature has an even bigger role in process efficiency since the reaction between amines and CO2 is temperature sensitive. In addition, temperature plays a significant role in ensuring a good heat balance across the process. Knowing temperature distribution across the entire length of the absorber and desorber is important in managing the process.

Minimizing complexity

An amine capture unit is part of the larger CCUS value chain, stretching all the way from the initial process or combustion application, to final underground storage or other ultimate disposition. Putting these processes together so all steps function optimally from end-to-end often requires outside help from the outset to create an effective system. Emerson’s Engineered Solutions Team can assist in any and all phases of a project, including:

- System software and services for monitoring and process control.

- Flow meters and flow computers for process and custody transfer.

- Analyzers for process gas and emissions.

- Gas chromatographs for purity evaluation.

- Corrosion and erosion monitoring.

- Consultation, and more.

As a global innovator, Emerson has a deep legacy of solving the most complex challenges facing process plants and related facilities. We combine advanced technologies, industry-leading expertise and an insatiable curiosity about the world around us to create sustainable solutions.

Emerson’s vision for industrial architecture is built on a consistent, cohesive software ecosystem from intelligent field devices to the edge, and to the cloud. This approach integrates operations to make all data instantly accessible, understandable and usable for analytics, innovation and performance improvement.

About the Author

Don Fregelette

Vice president for the chemical industry at Emerson

Don Fregelette is the vice president for the chemical industry, overseeing the global chemical and sustainability business at Emerson. Since joining the company in 1994, Fregelette has held several roles, including vice president of the Americas, vice president of global lifecycle services and vice president of strategic accounts and projects. Fregelette earned his bachelor of science degree in chemical engineering from the University of Buffalo, and an MBA in technology management from Rochester Institute of Technology.