NewTek protects position sensors in isolation tubes to eliminate failures in valve control and pump displacement sensing

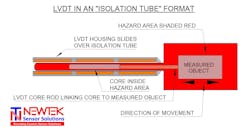

NewTek offers its Linear Variable Displacement Transducers (LVDTs) in an isolation tube format to ensure the highest reliable displacement feedback of hydraulic/non-hydraulic pumps and valves. The isolation tube protects the LVDT core from pressurized environments and fluids when the sensor measures pump flow or valve position (open/closed). The position sensor provides electronic feedback as part of a process control system.

In the isolation tube configuration, only the LVDT core lies inside the harsh area or media. Constructed of metal, the core can withstand exposure to a variety of fluids and pressures so that the chance of LVDT core failure is virtually nonexistent. With sensor windings in near ambient conditions, there is a low risk of unit failure. In an unlikely failure, the AC-operated LVDT is accessible without disassembling a complicated valve housing. The LVDT housing is easily replaced while the core stays inside the valve.

For customers wanting to monitor the position of a hydraulic valve stem but do not have room for a vented LVDT or the budget for hermetic feedthrough, the isolation-tube configuration is both an economical and reliable solution. The isolation tube proves superior to venting an LVDT as there is no need to run electricals out of the sensor via a high-pressure header or feedthrough. The core can tolerate temperatures and pressure that can cause trouble for a vented LVDT.

AC-operated LVDTs are ideal for valve and pump displacement sensing as the material between the core and housing can change the sensitivity of pre-calibrated DC units in highly pressurized environments. In addition to offering a range of standard AC-LVDTs, NewTek customizes sensors to accommodate a particular tube or calibrate with a smaller core so that an LVDT can fit into smaller spaces.

The Newtek NTC600 LVDT Signal Conditioner powers AC-operated position sensors and provides a digital output in a voltage, 4-20 mA current, or RS-485 digital format. This smart signal conditioner self-diagnoses LVDT failure, disconnects, or short circuits and offers cybersecurity lockout and tamper detection.