The Vortab Company offers new video for flow conditioning technology

For engineers challenged by flowmeter inaccuracy and repeatability issues in crowded plant conditions, a new video featuring Vortab Flow Conditioners explains how air, gas and liquid flow measurement can be greatly improved where restricted pipe runs in cramped equipment areas make following the flowmeter manufacturer’s pipe straight-run requirements impractical or impossible.

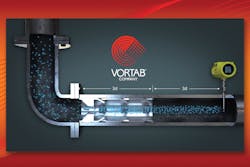

The Vortab flow conditioners overcome this challenge by delivering a uniform, swirl-free flow profile to the meter inlet in as little as a few pipe diameters for accurate, repeatable measurement. Upstream flow disturbers, such as pumps, elbows, expanders or reducers, and valves, often produce non-uniform, non-repeatable and swirling fluid flow entering the meter. These flow disturbers impact the flow sensor’s ability to measure fluid flow accurately and consistently.

Turbulent flow conditions in the pipe not only affect flowmeter accuracy but also damage pumps, valves and other equipment by causing premature wear that requires additional maintenance cycles and/or early equipment replacement before their normal life cycle. Swirling flows also can affect product throughput, energy costs, process quality and more.

With their exclusive flow profile and anti-swirl tab design, the Vortab process flow conditioners correct fluid disturbances to mimic adequate pipe straight run and produce a highly repeatable, symmetrical flow profile. Vortab flow conditioners are proven to be the industry’s lowest pressure drop flow conditioning technology, which reduces energy costs and minimizes process design considerations. Their use also eliminates the extra pipe cost and technician labor for additional lengths of pipe straight run and/or moving equipment around to accommodate new pumps.

In long lengths of straight pipe, swirl reduction and velocity profile correction occur naturally due to diffusion, friction and turbulent mixing. The Vortab Flow Conditioner’s anti-swirl and inclined vortex generating profile correction tabs, projecting from the inside pipe surface, generate vortices that accelerate these natural pipe effects to create a uniform, non-swirling, symmetrical flow profile in a much shorter section of pipe.

Watch the video here: https://www.fluidcomponents.com/news-events/demos-videos/flow-conditioners/vortab-flow-conditioners.