Versatility, innovation and reliability drive vortex flowmeter market growth

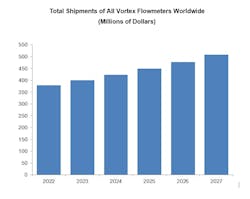

Wakefield, Massachusetts; May 28, 2024 (Flow Research release) — A new Flow Research study finds that the market for vortex flowmeters totaled $380 million in 2022, with China capturing the largest revenue volume (26.1 percent of the worldwide total) among the eight geographic regions, followed by North America and Western Europe. The World Market for Vortex Flowmeters, 7th Edition (www.flowvortex.com), projects a compound annual growth rate (CAGR) of 6.0 percent per year through 2027. China and the Asia/Pacific regions are expected to experience the fastest growth in the vortex flowmeter market.

Vortex flowmeters’ versatility, reliability, and accuracy at an economical price continue to drive steady market growth. As demand to measure steam and gas grows, vortex meters’ flexibility in measuring various fluid types – especially steam – is a distinct advantage and an important growth factor.

Vortex meters adapt to a wide range of applications

Applications for vortex flowmeters cover a wide range, representing the versatility that this flowmeter technology brings to users and the breadth of configurations available.

Mass flow measurement – important in custody transfer applications or when fluid temperature or pressure compensation is required for more accurate measurements – is one of the faster growing applications in nearly all flowmeter technologies. Vortex flowmeters can be equipped to measure mass flow as well as volumetric flow, and this has become an important product attribute.

The use of vortex flowmeters in oil & gas production, transportation, and refining continues to be to be a source of significant revenue strength. The world has a long-term energy need that will get more serious as populations grow and development continues. Custody transfer of natural gas is a fast-growing market, especially with the increased popularity of natural gas as an energy source. In 2017, the American Petroleum Institute (API) adopted a standard for using vortex flowmeters for custody transfer of gas, and it is likely that the approval has had an impact on their use in the energy industries.

The largest single application for vortex flowmeters worldwide, however, is in non-custody transfer of steam. Steam is a relatively difficult fluid to measure due to its two-phase characteristics. It is so difficult that neither Coriolis nor ultrasonic technologies have been able to make significant inroads into this application, and magnetic technologies are essentially excluded. Vortex meters are technically well suited for measuring the flow of both gas and steam, and their use is keeping pace with industry growth. Vortex flowmeters tolerate steam’s high process temperatures and pressures. They also provide wide rangeability that allows steam flow measurement at varying velocities in different points along the manufacturing cycle.

Multivariable vortex flowmeters are particularly attractive for steam and gas flow measurement and are contributing to vortex flowmeter market growth. Multivariable vortex meters were first introduced in 1997 through a joint venture with VorTek and Sierra Instruments. Since then, other suppliers have introduced multivariable vortex flowmeters, which now account for nearly 24 percent of total vortex flowmeter revenues. Multivariable vortex meters measure the volumetric flowrate as well as either the process flow temperature and/or pressure, and use that information to determine volumetric flow, temperature, pressure, fluid density, and mass flow. Mass measurements reduce the uncertainties inherent in volumetric measurements which, by themselves, cannot fully account for pressure and/or temperature changes in the fluid flow – problematic when the meter is used in gas flow applications.

A limitation cited regarding vortex flowmeter measurement capability has been its performance in low flow conditions. By its very nature of operation, the shedder bar must be immersed within the flowstream to generate swirling vortices downstream that are measured to determine actual volumetric flowrate. Low flow conditions lack the fluid velocity to create the required vortices. However, several manufacturers now offer models with reduced bores at the measurement point that enable vortex flowmeters to more effectively and accurately measure low flows. In addition, installation costs are typically lower than for standard bore meters, which have more upstream/downstream straight-pipe length requirements.

Both single-line size and double-line size reduced bore vortex flowmeters have become increasingly popular and revenues from these types are projected to continue to grow through 2027.

In response to user demands for increased reliability in a variety of applications, manufacturers have introduced two redundant vortex meter configurations: 1) a single shedder bar with dual sensors and 2) dual vortex meters calibrated and installed in tandem directly in the flowstream. Both ensure a higher degree of measurement certainty and reliability. Although the traditional installation with a single shedder bar and sensor still dominates the market, the new study determined that users see the value of measurement redundancy and that suppliers can achieve higher growth rates by promoting the dual configurations.

According to Dr. Jesse Yoder, president of Flow Research:

“The vortex flowmeter market is strong and positioned for growth, especially in gas flow measurement. Vortex flowmeters are versatile, accurate, and economical – many vortex meters offer accuracy readings of better than one percent, depending on the fluid and application. They can measure liquid, gas, and steam flow with equal ease. They are widely used for steam flow measurement and can handle the high temperatures of superheated steam. They also have very favorable costs of acquisition, commissioning, and ownership. These factors make vortex meters attractive to industrial companies striving to trim energy and other expenses, explore energy usage as a cost center, and ensure compliance with International Organization for Standardization (ISO) standards.”

About Flow Research

Flow Research is the only independent market research company whose primary mission is to research flowmeter and other instrumentation products and markets worldwide. Flow Research, founded in 1998 in Wakefield, Massachusetts, specializes in flow measurement devices, and conducts market research studies in a wide variety of instrumentation areas. These studies are developed through interviews with suppliers, distributors, and end users. Topics include all of the flowmeter technologies – both new and conventional – as well as temperature sensors, temperature transmitters, level products, and pressure transmitters. The company has a special focus on the energy industries, especially on oil and gas production and measurement. For more information, visit www.flowresearch.com or call +1 781-245-3200. For information on the vortex flowmeter study, visit www.flowvortex.com.