Understaffed Companies Turn to Automation Services Suppliers

Due to the global recession over the past few years, companies are coping with staffing issues and automation systems that are rapidly approaching the end of their useful lives. As such, ARC says users are relying on automation suppliers to fill the gaps. As they are asked to do more, the major suppliers are working to enhance and promote their main automation contractor (MAC) concept, working in a variety of capacities with engineering, procurement, and construction firms (EPCs), whether it is as MAC, Main Automation Vendor (MAV), Main Electrical Contractor (MEC), or a combination of two or more roles.

ARC says operating environments remain tight and reduced demand has forced companies to cut costs wherever possible. This includes both operating costs where there are huge untapped opportunities, and project costs, which are edging up to their pre-recession levels. Material costs have increased in the past several months along with increases in construction and labor costs associated with the recent spike in oil prices are driving these costs to record levels. With the recent unrest in Northern Africa and the Middle East and natural disasters in Japan, ARC believes costs will continue to rise.

The result is that users will continue to rely on suppliers more than ever to provide a continuously expanding scope and depth of automation-related services and a single point of coordination for their engineering projects. Project pipelines are beginning to fill up again and suppliers need to be prepared to handle the increased workload, according to ARC.

One of the biggest overall trends in the past decade is for automation suppliers to fill the role of main automation contractor. Demand for MACs, which can provide a single point of responsibility for all automation-related aspects of a project, has never been higher, according to ARC. This is due to factors on both the end-user and supplier sides of the business. End-users are under increased pressure to lower the cost of capital projects, find experienced and qualified personnel to execute projects and operate their plants, and reduce operating costs.

There are also the issues of operational costs, lifecycle costs, and plant performance. For the end-user, the project is only the beginning. Decisions made in the early stages of the project have an impact throughout the plant lifecycle. Data captured during plant construction must be seamlessly transferred through the operational phase. The MAC often provides maintenance and other after-market services beyond the startup phase, which ARC says can reduce risks and operational costs in the long run as well.

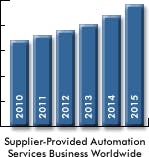

For more information on ARC”s “Supplier Provided Automation Services Worldwide Outlook” study, click here.