Ethernet Will Outpace Fieldbus in Industrial Automation Sector, Study Shows

RELATED: Top 5 Trends in Manufacturing Automation

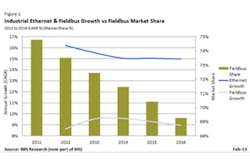

The future is still strong for fieldbus, with new connections still increasing year-on-year. However, IHS says it is undeniable that industrial Ethernet growth will remain higher than that of fieldbus. IHS said it believes that within 10 to 15 years industrial Ethernet will be the dominant networking technology in industrial environments and almost all components will offer Ethernet connectivity as standard.

IHS says long product lifecycles and conservatism in industry will maintain fieldbus in the near term but eventually it will be relegated to a supporting role. “With the reduction in adoption will likely come an increase in cost also, further fuelling the transition to industrial Ethernet,” Moore says.

For more information from “The World Market for Industrial Ethernet and Fieldbus Technologies – 2013 Edition” visit www.ihs.com.