Overcoming control valve trim selection challenges

Specifying a control valve correctly can be a challenging task. While configuration assistant programs are available to perform the sizing calculations, gathering the correct data to feed those programs can be difficult, and determining the proper valve flow characteristic can be problematic. While most end users understand the differences between quick-opening, linear and equal-percentage trims, far fewer understand the decision process for correct flow characteristic selection.

An incorrect trim selection can make control difficult or even impossible, so choosing the proper characteristic is critical to valve performance. This article describes the different control valve flow characteristic options and explains how to pick the best one to provide precise and consistent control across a variety of process conditions.

Quick opening, linear or equal percentage

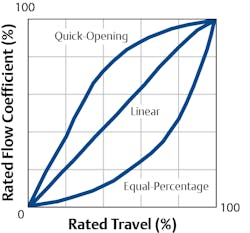

Available control valve inherent flow characteristics usually fall into three major categories: quick opening, linear and equal percentage. The flow profile is usually the result of the valve body construction as well as modification of the trim. The rated travel percentage versus the rated flow coefficient percentage for the three categories are shown in Figure 1.

As the graph shows, the three trim profiles are significantly different. The linear flow characteristic draws a flat line as its name suggests — with valve travel and flow capacity changing at roughly the same rate. When the valve is 50% open, the valve will regulate flow to about 50% of capacity. Globe valves, and some butterfly valves, typically exhibit a linear inherent characteristic.

The quick-opening profile also mirrors its name — with flow rising quickly as the valve first opens. A quick-opening trim will usually provide approximately 50% of flow with the valve only 25% open and 70% or more of flow at 50% opening. After that point, the flow rises very little as the valve strokes from 50% to 100%. Quick-opening trim is rarely used in control valves.

Equal-percentage trim is the opposite of quick opening, and flow is minimal as the valve begins to open. In fact, the valve may flow at 25% capacity or less when the valve is 50% open. However, as the valve moves from 50% to 100%, the flow increases quickly, adding an additional 50% of flow in the last 20% to 25% of travel. Ball valves, some high-performance butterfly valves and globe valves, each with equal-percentage trim, exhibit this inherent characteristic.

Such a wide variation of performance begs the obvious questions: Why are so many choices offered? Which is the right choice for a particular application?

The big picture

The first step to understanding the trim selection process is realizing the host automation system wants to see a linear response when it moves the valve. Most control valves operate as the final control element in an automated proportional integral derivative (PID) loop — with a process measurement, the process variable (PV), sent to a host system. The host system compares this measurement to the set point and sends an appropriate output to the valve.

Whether the PID controller moves the valve from 10% to 15% or from 85% to 90%, the PV should change the same amount, and ideally, the percent increase in PV should match the valve change, so the PV should change about 5% in either case.

When the system response is not linear, a PID controller can experience significant stability problems. In a nonlinear system, if the controller is tuned for one valve position, for example 15% open, it will perform well at that point. However, if the valve needs to open to 85% to provide significantly more flow, the nonlinear system response at that valve position will be very different, and the loop may oscillate badly. In fact, the loop may not be able to control in automatic mode at all.

Based on those concepts, one might conclude the best valve choice would exhibit a linear flow characteristic, but in many situations, this is not correct.

Valve response versus installed response

The desired goal is to achieve a linear installed response. However, the flow response of a valve is determined not only by the inherent characteristic of the valve trim but also by the differential pressure across the valve. Unfortunately, for most piping systems, the differential pressure across the valve varies greatly with flow. Consider the equipment arrangement in Figure 2.

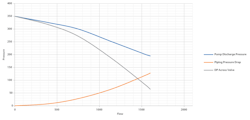

In this rather common system, a centrifugal pump is moving liquid through a control valve and a long length of pipe to a downstream vessel. The blue pump curve (see Figure 3) illustrates how the discharge pressure of a centrifugal pump falls with flow. The orange piping pressure drop curve illustrates that line pressure drop rises with the square of the flow. The difference between the pump discharge pressure and the piping pressure drop is the differential pressure across the valve (valve DP), and this curve is shown in gray.

Note the very high valve DP values at low flow rates and how the DP falls significantly as the flow increases. Now imagine how a linear characteristic trim valve would perform in this service.

At low flows, the slightest valve movement would result in a very large flow increase due to the high pressure drop. But at high flow rates, the valve would need to travel a significant distance to impart any change in flow due to the very low valve DP. Therefore, a linear characteristic valve would respond in a nonlinear way in this application.

At low flows, a slight valve movement creates a large change in flow. At high flows, the same valve movement barely changes the flow. Tuning this PID control loop would be extremely difficult or even impossible.

If an equal-percentage trim were installed, the nonlinear response curve of the valve would counteract the effect of the falling valve DP. At low flow rates, the equal percentage valve would need to move a large amount to change the flow opening, countering the effect of the high DP. At high flows, a slight valve movement would increase the flow capacity quickly, which is necessary since the DP across the valve is very low. As counterintuitive as it might seem, very nonlinear equal-percentage trim provides a near-linear system response in this application.

Flow characteristic trim selection rules of thumb

Different applications favor different valve flow characteristics. These rules of thumb do not cover every case, but they address many typical situations encountered in the process industries.

Linear control valves are usually chosen for pressure control with near-constant valve DP, near-constant inlet pressure with critical pressure drop, high inlet pressure with low outlet pressure (such as steam pressure letdown valves), positive displacement compressor bypass valves, distillation/fractionation column pressure control applications and others. Linear valves are also chosen for level control applications with a near-constant valve DP, temperature control applications throttling a liquid to a heat exchanger or the use of two valves or a three-way valve in heat exchanger bypass applications.

Quick-opening valves generally do not work well as control valves but can be utilized for drain/vent applications where flow is needed quickly.

Regardless of the service and selected flow characteristic trim, a valve must first and foremost be sized appropriately. Valves are often oversized to provide a margin of error in applications where process conditions have not been investigated thoroughly, but this will usually result in poor control regardless of the trim selection.

Conclusion

Choosing the correct inherent flow characteristic can make the difference between a successful control valve installation and an erratic automated loop control nightmare. The idea of achieving a linear installed response is simple enough, but to accomplish this goal, end users must possess a good understanding of their process. Discussing the flow dynamics with process experts can yield big dividends in terms of controllability and process stability.

Mark Nord is the control valve solution architect for Emerson’s Flow Controls products in Marshalltown, Iowa. He is responsible for solving challenging control valve applications. Nord has 30 years of experience in plant operation, control valve and steam conditioning applications, and he holds a BSME from the University of North Dakota.

About the Author

Mark Nord

Mark Nord is the control valve solution architect for Emerson’s Flow Controls products in Marshalltown, Iowa. He is responsible for solving challenging control valve applications. Nord has 30 years of experience in plant operation, control valve and steam conditioning applications, and he holds a BSME from the University of North Dakota.