A complete guide to thermal mass flowmeter technology

As a leading manufacturer of high-performance thermal mass flowmeters, we regularly address key questions about these precision instruments and their applications in gas flow measurement. This comprehensive guide explores the fundamental principles of thermal mass flowmeters, their distinct advantages over conventional flow measurement technologies, and the diverse applications where they excel.

What is a thermal mass flowmeter?

A thermal mass flowmeter is a precision instrument that directly measures gas mass flow using heat transfer principles. Unlike other flow measurement technologies, thermal mass flowmeters don’t require additional temperature or pressure compensation and deliver accurate readings regardless of most operating conditions.

Actual flow versus standard flow

Gas is compressible, making accurate measurement of gas flow rates challenging. As temperature increases, gas molecules move further apart. Conversely, as pressure rises, gas molecules move closer together.

Most gas flowmeters (differential pressure, turbine, positive displacement, vortex shedding) measure gas flow at actual operating conditions where the measurement is made, often called Actual Cubic Feet per Minute (ACFM). However, what’s more important is the flow rate adjusted for a particular temperature and pressure, frequently referred to as Standard Pressure and Temperature (STP) and measured in Standard Cubic Feet per Minute (SCFM).

Most flowmeters require temperature and pressure correction to convert from ACFM to SCFM conditions. To determine mass flow rate in standard conditions, you need to measure the actual flow rate, operating pressure and operating temperature. This is not necessary with thermal mass flow technology.

How thermal mass flowmeters work

Thermal mass flowmeter technology measures heat transfer as gas flows past a heated sensor. These meters represent an entirely different method for measuring flow rate compared to traditional technologies.

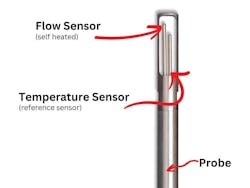

The Sage meter consists of two high-precision platinum sensors protected in stainless steel. The temperature sensor serves as the reference and measures gas temperature. The flow sensor is heated to maintain a slight temperature difference (overheat) above the temperature sensor

As gas flows past the heated flow sensor, heat transfer occurs. The instrument measures the power required to maintain the desired overheat, which is proportional to the mass flow rate. The amount of energy applied to the sensor is very low, allowing this technology to be used safely with natural gas, hydrogen or other flammable gases.

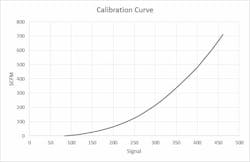

Thermal mass flow measurement is an inferred flow measurement. These meters measure heat transfer and then relate it to mass flow rate based on NIST traceable calibration. During calibration, known amounts of gas flow past the sensor while the signal is measured multiple times across the instrument’s operating range. A curve showing signal vs. flow rate is created for each meter (Figure 2)

Advantages of thermal mass flowmeters

Thermal mass flowmeters offer significant advantages over other flow measurement technologies:

- Direct Mass Flow Measurement: No need for pressure or temperature corrections

- Superior Low-End Sensitivity: Accurately measures even minimal flow rates

- Exceptional Turndown Ratio: Typically 100:1 with resolution as high as 1000:1; higher turndown is available in optimal conditions.

- Easy Installation: Simple insertion or inline installation options

- No Moving Parts: Ensures long-term reliability and minimal maintenance

- Low Pressure Drop: Conserves energy with negligible flow restriction

- Versatility: Effective across a wide range of pipe sizes and applications

Top applications for thermal mass flowmeters

Thermal mass flowmeters excel in numerous industrial, commercial and environmental applications. Here are seven key areas where these instruments deliver exceptional performance:

#1. Natural Gas to Combustion Sources

Combustion sources such as boilers and furnaces have different efficiencies. Users can determine the more efficient operation by measuring natural gas flow rates to combustion sources. Thermal mass flowmeters are ideal for measuring natural gas flow rates to individual combustion sources.

#2. Natural Gas Submetering

In facilities with different cost centers, submetering natural gas is frequently performed for cost allocations. When utility costs are allocated to various departments, there’s an increased incentive to improve efficiency and reduce natural gas usage.

#3. Compressed Air

Industrial air compressors use more electricity than most other industrial equipment and can account for as much as a third of energy consumption in a plant. Thermal mass flowmeters help determine the optimal number of compressor units needed. Additionally, air leaks waste up to 30% of an industrial compressor’s output. These meters help define the extent of leakage in a system and quantify the lost energy.

#4. Biogas Production

Biogas is produced in landfills as landfill gas and in anaerobic digesters as digester gas, among other places. High in methane, it’s often the focus of biogas-to-energy projects. Accurate gas flow measurement is needed throughout production, whether monitoring biogas destruction or cogeneration. Specific gas flow is also necessary for GHG emissions reporting to environmental agencies and carbon credit programs.

#5. Flare Gas

Flare gas measurement and monitoring ensure the system operates correctly. Varying gas compositions complicate this application. Thermal mass flowmeters provide reliable measurement in these challenging conditions.

#6. Aeration Air

The activated sludge process used at wastewater treatment plants requires an air flow for microorganisms to break down organic waste. An optimum air flow throughout the system, sufficient to encourage waste consumption by microorganisms (yet not excessive), is continuously sought.

#7. Combustion Air

Optimizing air-to-fuel ratios through accurate and repeatable gas flow measurement achieves combustion efficiency and effective energy management. Direct measurement of combustion air flow and fuel flow provides the criteria for peak efficiency.

Frequently asked questions about thermal mass flowmeters

How accurate are thermal mass flowmeters?

Thermal mass flowmeters typically achieve accuracy ratings of ±1% of reading plus ±0.5% of full scale. This high accuracy, combined with excellent repeatability of ±0.2%, makes them ideal for critical gas flow measurement applications where precise readings are essential for optimizing system performance or meeting regulatory requirements. If needed, accuracies can be enhanced via flow conditioning or custom testing.

Do thermal mass flowmeters work with all gases?

No. Thermal flowmeters cannot measure condensing gases; dry or slightly humid gases are best. Also, each gas has different thermal properties that affect heat transfer rates, so for optimal performance, the meters should be calibrated using the actual gas composition for which the meter is intended. When ordering a thermal mass flowmeter, specify the gas to be measured to ensure proper calibration. For applications with variable gas compositions, such as biogas, variational adjustments to the gas mix can be made during the calibration process.

What’s the difference between insertion and inline thermal mass flowmeters?

Insertion-style thermal mass flowmeters feature a probe that inserts directly into the pipe through a compression fitting or ball valve assembly. They’re ideal for larger pipe sizes (typically 2″ and above) and allow for easy installation without cutting the pipe. Inline models have the flow body integrated into the pipe section and are generally used for smaller pipe diameters (typically under 2″).

Can thermal mass flowmeters be used in hazardous locations?

Yes. Many thermal mass flowmeters are designed and certified for use in hazardous locations. Models like the Sage Paramount are available with Class I Division 1 approval, with Division 2 approval being standard, making them suitable for environments where flammable gases or vapors may be present. Always verify the specific hazardous area certification needed for your application.

How often do thermal mass flowmeters require calibration?

Traditional thermal mass flowmeters typically require annual factory recalibration. However, advanced models like those from Sage Metering feature in-situ calibration verification technology that allows users to verify calibration accuracy in the field without removing the meter. This innovative feature can eliminate the need for annual factory recalibrations while ensuring measurement integrity.

What communication options are available for thermal mass flowmeters?

Modern thermal mass flowmeters offer multiple communication options, including 4-20mA analog outputs, pulse outputs for totalized flow and digital communications like Modbus RTU, BACnet, HART protocol and Ethernet options. These communication capabilities allow for seamless integration with various control systems, energy monitoring software and building management systems. Additionally, the Sage Paramount has optional Bluetooth capability that permits remote programming of hard-to-reach integral-style meters.

How do thermal mass flowmeters handle varying flow conditions?

Thermal mass flowmeters excel in handling widely varying flow conditions thanks to their exceptional turndown ratio. With turndown ratios of 100:1 standard and higher in some models or applications, they can accurately measure both very low and high flow rates. This makes them ideal for applications with fluctuating demands or seasonal variations.

Conclusion

Since gas is compressible, its volume changes under pressure or when heated (or cooled). Thermal mass flow measurement is based on heat transfer and measures mass flow, not volumetric flow, thus eliminating the need for temperature or pressure correction.

Thermal mass flowmeters deliver significant advantages for gas flow measurement applications. By directly measuring mass flow based on heat transfer principles, these instruments provide exceptional accuracy across various conditions while simplifying installation and reducing maintenance requirements.

About the Author

Fred Whorff

Vice President of Sales & Business Development for Sage Metering

Fred Whorff is the Sage Metering president. He has over 30 years of experience in product design and applications of flow measurement and control products. He holds patents on several flow technologies. As a hands-on engineer, he also has considerable field experience in various industries.