Comparing displacer transmitter technologies for liquid level metering

Process level measurement has greatly evolved over the years with new technologies. Instrumentation engineers have more demanding requirements that make it essential to have reliable and accurate liquid level measurements. Through the evolution of liquid level measurement technology over the years, one of the most trusted devices for continuous liquid level measurement remains the displacer level transmitter.

Displacer transmitters operate on the Archimedes principle of buoyancy, which holds that any object, wholly or partially immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object. As liquid level moves upward on the displacer, the buoyancy force increases and there is a vertical motion that can be converted to liquid level using sophisticated software.

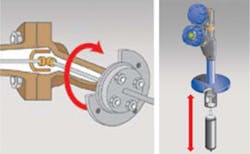

The two main technologies that are used as displacer level transmitters are torque tubes and range spring/LVDT (Linear Variable Differential Transformer) technologies. A torque tube uses a torsion bar that rotates relative to the weight of the displacer in fluid to correspond to a level reading. The range spring and LVDT combination uses an LVDT core that moves as the spring is unloaded by having fluid on the displacer, causing voltages to be induced across the secondary windings and be converted to a level reading.

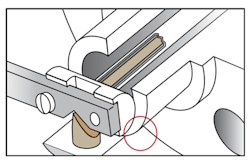

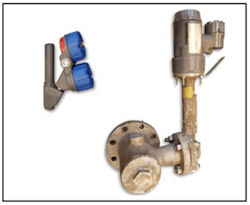

Tourque tube technology (left) and range spring/LVDT technology (right). Image courtesy of Magnetrol International.

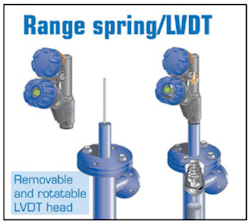

There are substantial technology advantages that can make using range spring/LVDT based displacer transmitters preferable to a torque tube-based instrument. These include improved accuracy, structural integrity, footprint, and maintenance capability.

Measurement Accuracy

The main technology advantage is a more accurate level output given by a range spring/LVDT displacer transmitter. Demonstrated through extensive testing1, the output of a range spring/LVDT displacer transmitter is four times more resistant to vibration, six times more linear, and 20 times more accurate than a torque tube.

[1] Vibration testing completed between Fisher 2500 Leveltrol and Magnetrol Modulevel. Linearity and repeatability testing done between Fisher DLC3010 with 249BF torque tube and Magnetrol E3 Modulevel. Image courtesy of Magnetrol International.

When monitoring the process level, it is important to have the most accurate level measurement, as inaccuracies can cause inefficiencies and cost end users money. The range spring helps dampen any vibration that may occur to the level instrument, maintaining a more stable output than a torque tube. The linearity and repeatability contribute to a consistent level output, ensuring the transmitter reads consistently throughout its operation. If there is any sticking in the transmitter, it could cause the level reading to be different from the actual level.Torque tube liquid level measurement is susceptible to fatigue failure and accelerated corrosion. Image courtesy of Magnetrol International.

Structural Integrity

The structural integrity of the displacer transmitter is important to ensure minimal maintenance costs across the life of the instrument. There are two structural components that separate range spring/LVDT technology from torque tubes. The torque tube arm that holds the displacer is mounted on what is called a knife edge. This edge creates a stress concentration on the part, which can create wear over time to cause a failure. The range spring and stem attached to the LVDT core move vertically, completely eliminating the occurrence of friction or wear. The LVDT core is coated with a polymer material to provide smooth vertical motion, and the range spring is protected by a spring cup.

The static-pressure-retaining enclosing tube on spring/LVDT liquid level measurement technology is not susceptible to fatigue failure or accelerated corrosion. Image courtesy of Magnetrol International.

The other component that affects structural integrity is the thickness of the pressure boundary components. In a torque tube displacer transmitter, the torque tube itself serves as the pressure boundary component and has a thickness of 0.01". In contrast, the enclosing tube for the range spring design is 0.035" thick. The increased thickness helps contain pressure and has more tolerance against any type of corrosion that would erode material away, since these components are exposed to the process media. Also, because the torque tube rotates, there is shear stress induced into the material, to which the enclosing tube for the range spring/LVDT design is not susceptible.

Installation Footprint

Space, while maybe not top of mind when picking a level sensing technology, can play an important role in the selection of the type of level transmitter. Some applications have space constraints and are not a good fit for a device with a large footprint. Torque tube and range spring/LVDT models have very similar sensing elements that use a displacer, but the difference is in the size and area of the transmitter heads. Torque tubes have a very large footprint when including the level transmitter, and users of this technology are also confined to a left-hand or right-hand display design. The left hand or right hand design can cause limitations in how wiring is configured, as the location of the electronics conduit is fixed. For range spring/LVDT designs, a vertical and fully rotatable housing head is available to cover a smaller amount of area, allowing for easy wiring depending on where the wiring is coming from.

Range spring/LVDT technology transmitter (left) vs. torque tube transmitter (right). Image courtesy of Magnetrol International.

Maintenance

Finally, most level transmitters that have moving mechanical parts will typically require maintenance to keep them operating at peak performance. Displacer transmitters are electro-mechanical devices that require some level of maintenance during their operating life.

It is critical, therefore, to consider long-term maintenance efficiencies in device selection. One key consideration is the minimization of wear points in the device design. As discussed above, torque tubes consist of a knife edge that the sensing element rotates on and can wear over time. Another key maintenance factor is downtime. Since the torque tube itself is part of the pressure boundary, if the transmitter requires maintenance, the pressure vessel will have to be de-pressurized. This creates downtime that negatively impacts end users’ bottom line costs.

Range spring/LVDT liquid level measurement features a removable and rotatable transmitter for installation flexibility. Image courtesy of Magnetrol International.

For range spring/LVDT technology, the pressure boundary component is not part of the sensing element. Therefore, if troubleshooting is required on the range spring/LVDT transmitter, it can be removed without having to de-pressurize the entire system. This equates to less downtime and maintenance cost savings.

This content is sponsored by Magnetrol International. Sponsored content is authorized by the client and does not necessarily reflect the views of the Process Flow Network editorial team.

![[1] Vibration testing completed between Fisher 2500 Leveltrol and Magnetrol Modulevel. Linearity and repeatability testing done between Fisher DLC3010 with 249BF torque tube and Magnetrol E3 Modulevel. [1] Vibration testing completed between Fisher 2500 Leveltrol and Magnetrol Modulevel. Linearity and repeatability testing done between Fisher DLC3010 with 249BF torque tube and Magnetrol E3 Modulevel.](https://img.piprocessinstrumentation.com/files/base/ebm/fcn/image/2017/08/PFN-20170912-AD-2657-Magnetrol_NativeEmail_Figure2.png?auto=format,compress&fit=max&q=45?w=250&width=250)