Pipeline applications include periodically spaced isolation valves for segmenting the pipeline in the event of a leak or the need for other service. These valves are typically full-ported gate or ball valves, which provide low pressure drop when fully open, tight shutoff when closed, and full porting to permit pipeline pigging.

The total investment for a 200 mcfd gas processing plant would be $150 million and would require an expenditure of $5 million for valves. Twenty percent of this investment would typically be for control, with 80 percent for on/off service.

An LNG liquefaction plant can cost $8.3 billion. The valve portion would be 1 percent or $83 million. There are a number of liquefaction projects underway in the U.S. due to the abundance of shale gas.

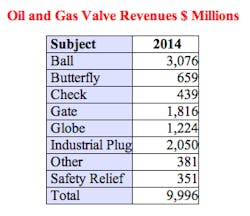

For more information on Industrial Valves: World Markets, click here.