Critical measurements and best practices for future-proofing the refining industry

Critical measurements for existing refineries and integrated refineries

There is a lot of commonality for the critical measurements between standalone refineries and refineries with integrated petrochemical facilities. In both cases, improving energy efficiency and reducing emissions will be critical for long-term profitability and viability. Operators should focus on having accurate, reliable or real-time measurements that can aid in mass and energy balances, fired heater combustion optimization and critical asset monitoring.

Mass and energy balances

One of the first principles for reducing and managing energy consumption is measuring what you need to manage. Both mass and energy balances are critical for understanding losses and optimizing operations. With integrated complexes, products from refineries are sent to petrochemical units as feedstock for processing and allocation of utilities between the operations. Although refineries control on a volume basis, directly measuring mass for unit yield and charge streams and custody transfer of products and raw materials is a best practice. The accuracy of volumetric flow technologies is often dependent on flow profile and fluid properties such as density. As a result, measurement inaccuracies result when fluid compositions change — which can occur often, especially if a refinery is processing multiple crude slates.

Using Coriolis meters for facility and unit mass balance points is a best practice because the meter accuracy is independent of flow profile and changing fluid properties since mass is directly measured. Another best practice for improving facility mass balance is to reconcile custody transfer measurements from Coriolis meters against automatic tank gauging measurements. Accurate tank gauging measurements are important not only for custody transfer measurements, but also for accounting for inventory. Some of the best practices to improve tank gauging measurements include using a radar level technology that is immune to ambient temperature changes affecting the measurements and the use of a multi-spot temperature sensor to obtain a tank temperature profile and average tank temperature to reduce inaccuracies from stratification.

An equally important measurement for allocation purposes would be steam system measurements. Steam can be challenging to measure due to multivariable compensations required for various types of steam on a mass basis. Advancements in measurement technology including wireless solutions and integrated devices like vortex meters, Annubar flowmeters, multivariable meters and integrated compact orifice meters are designed to reduce leak points, gaskets, piping penetrations and runs, and impulse lines, which were traditional issues in obtaining reliable or cost-effective steam measurements.

Utilizing these measurement advancements and practices will provide more accurate mass and energy balances upon which losses can be identified and allocation measurements can be improved.

Combustion optimization

Optimizing the combustion performance for fired heaters should be a top priority in refineries and petrochemical facilities. Fired heaters are the top energy consumers in most refineries and petrochemical plants. In addition to energy efficiency, the control strategy of a fired heater is also a delicate balance between emissions and safety. Control of a fired heater is complex, and obtaining reliable feedback measurements can be challenging, especially for measurements like oxygen in the stack and air flow. In addition, fuel gas or natural gas composition variation is not compensated for in the control schemes. As a result, control of the fired heater is not very sophisticated. Traditionally, the only control loop employed is where the process outlet temperature dictates the amount of fuel to the burner and a pre-set level of excess air is used as a safety buffer to ensure sufficient air for fuel-rich conditions.

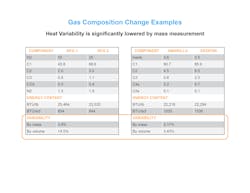

The fuel control scheme in heaters is often pressure or volumetric based. When fuel-rich conditions occur under these control schemes, the energy content of the gas increases and the air required for combustion increases. However, the air in natural draft fired heaters is not easy to quickly adjust, and as a result, the richer fuel consumes air at a faster rate, causing oxygen levels in the stack to rapidly deplete. This can result in heater trips. However, as shown in Figure 3, the heating content of the gas is more proportional and has less variability on a mass basis than a volumetric basis. Therefore, controlling on a mass basis by using a Coriolis meter can provide more stability in the control scheme and better stabilize the air required for combustion. This could allow the user to lower the target O2 in the stack. Operating with less excess air reduces emissions and improves efficiency. Typically, net present value savings of moving from a volumetric or pressure-based control scheme of fuel gas to a mass one is around $250,000 to $1 million.Critical asset monitoring

One of the top trends for improving energy management involves refineries and petrochemical processors investing in a second layer of automation focused beyond process control and larger equipment energy consumers to smaller consumers like pumps, steam traps and heat exchangers. Implementing continuous monitoring of smaller equipment like pumps, steam traps and heat exchangers was originally deemed as being cost prohibitive. As a result, smaller equipment monitoring had little to no instruments, was manually inspected or maintenance was scheduled or reactive. Wireless technologies enable quick, nonintrusive and cost-effective implementation of real-time measurements that can be used to monitor critical measurements such as pressure, level, temperature, vibration, acoustics and flow in smaller equipment and evaluate the asset’s health to detect changes in conditions that can affect efficiency. Combining the wireless measurements with pre-built analytic software tools enables early detection of issues, avoiding unplanned shutdowns and shifting maintenance from reactive or scheduled to predictive, resulting in savings up to 50% and investment payback in months.

Beyond efficiency returns, monitoring equipment like pressure relief valves and rupture discs can reduce emissions. An increased area of focus for both refining and petrochemical processors is flare monitoring, especially in the United States, as the EPA has increased flare monitoring requirements. Traditionally, relief valves were manually inspected on a periodic basis. Determining leaks was labor intensive and arduous since many valves are in hazardous or difficult-to-reach locations. By implementing acoustic, wireless technology for monitoring vibration downstream of valves and using analytics software, immediate identification and recording of leaks and events of the valves and rupture discs that feed to the flare systems can be determined and monitored for reporting and reducing emissions.Critical measurements for biorefineries

Although there are some similarities for biodiesel production compared to traditional refining, refineries that are adding or converting to renewable diesel production units will need to focus even more on measurement systems due to the high variation of feedstocks and reporting required for complying with the Low Carbon Fuel Standard (LCFS) of California.

The logistics and off-sites for renewable diesel plants vary from traditional refining as a majority of the feedstocks and products are entering and leaving the facility via truck and railcar loading and unloading, as opposed to pipeline and ship. Having an efficient measurement system such as a metering-based transfer system using Coriolis meters, as opposed to relying on weigh bridges, has safety, accuracy and efficiency advantages. Of the upmost importance is the accuracy and verification of the measurements of materials coming in and out of the plant in addition to all the utilities consumed for obtaining LCFS credits.

Other areas where leveraging Coriolis meters plays significant importance is in the pre-feed treatment unit and the reactor section. There are a number of contaminants in bio-based feedstocks that are not present in petroleum-based feedstocks, and these must be eliminated to protect the life of the hydroprocessing and isomerization catalysts used downstream. Treatment for the feedstocks will be more similar to food and beverage processes than they are to traditional refining processes. This can include drying, polyethylene removal, filtration, enzymatic degumming, chemical dosing and bleaching. Many of the reactions require stoichiometric ratios, mass-based reactions and concentration measurements for acids and caustic. Within the reactor section, the variability of feedstocks processed and, therefore, the variation of fluid properties can affect the accuracy of volumetric flowmeters, making Coriolis meters the preferred technology in this area of the plant, as well as to ensure optimum charge rates, purge rates and recycle ratios.

Another measurement of importance is corrosion monitoring. Renewable diesel plants have corrosion issues similar to hydrotreating and isomerization plants in traditional refineries with special attention required for amine units, air coolers upstream of separators and overhead systems in the fractionators. Feedstocks with higher values of fatty acids will tend to have more corrosion issues. Also, renewable diesel plants produce CO2 and water in much higher concentrations than normal refinery units, causing carbonic acid to form, which leads to more corrosion downstream of the reactor. Wastewater produced from the plant can also contain high levels of carbonic acid, leading to additional corrosion in the wastewater system. Corrosion management can successfully be implemented through cost-effective, nonintrusive wireless corrosion monitoring technologies and pre-built analytic software tools designed to provide trends and insights to make better asset integrity decisions.

Making and measuring the transition

The transition of the refining industry to a more sustainable future involves more than just a changing business model or feedstock and product slates. Digital transformation is affecting the practices in which we measure and manage our data. New measurement technologies and practices for measuring and managing emissions, energy efficiency and alternative feedstocks and products are enablers for paving a more sustainable future regardless of what path forward refineries take.

Meha Jha is the refining industry marketing manager for Emerson. Jha holds a bachelor’s degree in chemical engineering from Auburn University. Jha is focused on helping refiners leverage Emerson’s measurement and analytical instrumentation to improve safety, reliability, efficiency and optimization. She was selected for Emerson's Engineers in the Leadership Program.

Julie Valentine is the director of global refining measurement solutions for Emerson. Valentine holds a bachelor’s degree in chemical and petroleum refining engineering from Colorado School of Mines. She has authored numerous technical papers on various applications of flow technology in the refining industry and is the co-inventor of two U.S. patents for Emerson’s measurement solutions business.

About the Author

Meha Jha

Meha Jha a refining industry marketing manager for Emerson. Jha holds a bachelor’s degree in chemical engineering from Auburn University. Jha is focused on helping refiners leverage Emerson’s measurement and analytical instrumentation to improve safety, reliability, efficiency and optimization. She was selected for Emerson's Engineers in Leadership Program.

Julie Valentine

Julie Valentine is the director of global refining measurement solutions for Emerson. Valentine holds a bachelor’s degree in chemical and petroleum refining engineering from Colorado School of Mines. She has authored numerous technical papers on various applications of flow technology in the refining industry and is the co-inventor of two U.S. patents for Emerson’s measurement solutions business.