2014 Coal-Fired Project Starts to Reach $220 Bil.

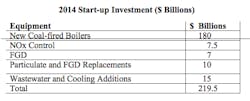

The combination of retrofits to existing power plants and start-up of new coal-fired power plants in 2014 represents a total investment of $220 billion, according to a report by the McIlvaine Company.

2014 will be a record year for new NOx control installations with 300 projects totaling over 110,000 MW, according to McIlvaine. Retrofit projects represent 50 percent of the total and would add $7.5 bill. to the total potential for 2014 (the other 50 percent are included in the new coal-fired boiler numbers).

McIlvaine predicts there will be 33,000 MW of FGD (flue gas desulfurization) retrofits, but a total of 95,000 MW of FGD projects starting in 2014 when the new power plants are included. This will add another $7 billion to the total purchases.

McIlvaine says there are a number of projects to replace precipitators and old FGD systems slated for 2014, which figure to add another $10 bill. to the total. There are also various initiatives for 2014 to upgrade wastewater treatment systems and add cooling towers to replace once through cooling systems, which are expected to add another $15 bill. to hardware purchases for 2014.