Industrial and manufacturing companies in the United States use close to one-third of all the energy consumed in the country on an annual basis. However, data shows such organizations also have high adoption rates for energy management initiatives and continue to spend on energy management products and services for new innovations.

A recent report by Pike Research indicates that industrial companies are quickly coming to the realization that energy and sustainability issues are a critical requirement for the competitiveness and even survival of their businesses. This realization will lead to significant growth in industrial energy management products and services.

According "Energy Management Systems for Industrial Markets," the U.S. market for industrial energy management software and services will rise from $960 million in 2011 to $5.6 billion by 2020, a compound annual growth rate (CAGR) of 21.6 percent.

Pike Research Vice President Bob Gohn says the energy management industry is entering a dynamic period of renewal and innovation. "New technologies are allowing greater insight into energy procurement and use, as well as the management of energy as an input to the industrial process," Gohn said in an April news release. "At the same time, a variety of assistance programs, plus new standards and certifications, are helping to drive energy performance initiatives into the organizational cultures of companies wishing to gain efficiencies in their industrial processes."

Among those new standards and certifications is ISO 50001:2011, Energy management systems—Requirements with guidance for use, published in June 2011 by the International Organization for Standardization (ISO).

Considered "groundbreaking" as the first international standard on energy management, ISO 50001 is intended to provide organizations, industrial plants and commercial facilities with a recognized framework for integrating energy performance into their management practices at every level of operation. The standard could have a positive impact on some 60 percent of the world’s energy use across economic sectors, ISO says, by providing public and private sector organizations with management strategies to increase energy efficiency, reduce costs, and improve energy performance.

With heavy support from the U.S. Department of Energy (DoE), ISO 50001 has been among the top 10 ISO bestsellers since it was published last June, according to Roger Frost, head of Communication Services for ISO. "The rapid success of ISO 50001 can be explained by the widespread recognition that the efficient and effective use of energy by organizations can have a significant effect on the bottom line, while contributing positively to environmental concerns and the overall need for sustainability," Frost said.

Early gains reported by companies that have adopted the standard include significant reductions in power consumption, carbon emissions, and energy costs, as well as benefits to manufacturing plants, communities, and the environment, ISO reports.

Although it’s hard to pinpoint exactly how many industrial facilities worldwide have been certified to ISO 50001 to date (ISO does not carry out certification, and there is no official worldwide database of certifications that are administered independently by certification bodies), there is an impressive international list of early adopters. According to an unofficial tally by Reinhard Peglau, Senior Scientific Officer on Environmental Management at the German Federal Environment Agency, since 2009 more than 300 European companies have received certification to either the British Standards Institution’s EN 16001 or ISO 50001.

Among early adopters was global energy management specialist Schneider Electric (schneider-electric.com). Schneider Electric’s headquarters building in France was the first building in the world to be certified to ISO 50001, according to Gilles Simon, Environment Manager for Schneider Electric. Five other Schneider Electric buildings located in and around Grenoble were certified in February 2012, and more locations are on their way to certification, Simon said.

In addition, a growing number of U.S. industrial companies have participated in the DoE’s Superior Energy Performance (SEP) demonstrations, including 3M, Coca-Cola, Dow Chemical, Spirax Sarco, and World Kitchen (the maker of Pyrex).

SEP is a certification program developed by the U.S. DoE and the Council for Energy Efficient Manufacturing (U.S. CEEM) to help organizations conform to the new energy standard.

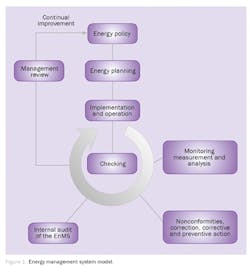

Source: ISO

What ISO 50001 Looks Like

Development of ISO 50001 officially began in 2008 with the United States and Brazil leading the ISO Project Committee 242 (ISO PC 242). In all, 56 countries have contributed to the development of the standard, which is an "enormous" number of countries for an ISO management systems standard, according to Aimee McKane, who works for the U.S. Department of Energy and Lawrence Berkeley National Laboratory (Berkeley Lab, lbl.gov). McKane spent 2010 working on the ISO 50001 standard, helping to lead it into its final form in her role as vice chair of the U.S. delegation to ISO PC 242. She recently presented an introduction to ISO 50001 as part of a Pumping Systems Matter Webinar, hosted by the Hydraulic Institute in April.

ISO 50001 is designed to be used independently or can be integrated with other management systems such as ISO 9001 (quality management) and ISO 14001 (environmental management). According to McKane, the standard is applicable to all organizations that use energy, establishing a framework for industrial and commercial as well as transportation organizations.

ISO 50001 incorporates the Plan-Do-Check-Act approach of existing ISO management system standards to encourage and support continual improvement. It not only provides a framework for addressing energy use and planning, but it also includes action plans and identifies methods for measuring and documenting improvements. Successful actions can be used to further improve processes throughout the organization.

According to McKane, what makes ISO 50001 somewhat unique is that it requires "reporting out" on energy performance—organizations must show that energy performance has improved. "You can’t just have a lovely looking, well-documented management system, it actually has to show measureable results in the way of that the energy performance is improved," she said. "Energy performance" to ISO means measurable results, i.e. improvement, of energy efficiency, energy use and energy consumption.

In a nutshell, ISO 50001 provides technical and management strategies for every level of an organization to set and reach goals to optimize its energy efficiency, lower costs, and meet environmental targets.

"Before ISO 50001, many of our locations already managed energy actions plans. But the standard, by giving us guidelines, gives us a strong structuring framework to monitor our improvement and management actions," Simon said.

Putting ISO into Action

Conformity to the standard can be done through self-evaluation or third-party certification.

According to Simon, the first step in the process of establishing an energy management program is to analyze energy use and performance. "During that step an energy diagnosis must be achieved by energy specialists," he said. "The delivery of such a diagnosis is a list of actions, which can be implemented the first year or the following years.?Then a measurement plan must be implemented: it is important to measure before acting.?Those two actions give you the basis to correctly manage your energy."

ISO 50001 does not require a facility to improve energy performance by a specific amount or within a given timeframe. That’s where programs like SEP come in. To help companies conform to the new energy management standard in the United States, the SEP certification program is underway with SEP for industry to be launched nationwide in October 2012. SEP for commercial buildings is currently in the demonstration phase. According to the DoE, approximately 45 U.S. industries have or are currently participating in SEP demonstrations to implement an energy management system and improve energy performance.

Accredited by ANSI/ANAB, SEP requires third-party verification of two main components: 1) conformance to ISO 50001, and 2) validated energy performance improvement. SEP calls for individual manufacturing facilities to look back and document at least a 5 percent energy performance improvement over a three-year period. SEP also offers a two-tier approach that accommodates for the maturity of facility’s energy management program, the level of external validation desired, and business climate/cycle.

Benefits of ISO 50001 Implementation

Overall, organizations worldwide are reporting energy cost savings from adoption and implementation of the new standard on energy management.

According to Simon, the first year Schneider Electric implemented its energy management program and the actions items its initial energy diagnosis delivered, it improved its energy consumption by 17 percent. "Most of our actions get a return on investment in less than three years," Simon said. "Additionally to that direct savings, managing energy gives us better costs management for the years to come."

Likewise, Dow Chemical Company’s manufacturing facility in Texas City saw a 17.1 percent improvement in energy performance, and its energy systems facility there saw an 8.1 percent improvement, as a result of participation in the DoE’s Texas Pilot Project for SEP.

For a global energy management company like Schneider Electric, the motivation to move to ISO 50001 certification was two-fold, Simon said: First, to gain the direct benefits from better energy management such as decreased energy bills, smaller carbon footprint, structured energy action plans; and second, to demonstrate leadership in energy efficiency and further develop expertise in energy management.

"The outside validation is a strong motivation enforcement for all our employees," Simon said. "Moreover, it is also a recognition of our leadership in these fields; we can show to our customers that the energy efficiency solutions we propose to them are efficient, and we can show it in our buildings."

International companies will also be able to use ISO 50001 to standardize energy management across operations in different countries. "EN 16001 prepared us to energy management," Simon said. "But Schneider Electric is a worldwide company, so an international standard fits better to our locations all around the world. Moreover, ISO 50001 goes further (than) EN 16001 on several important requirements."

Amy W. Richardson is the managing editor of Flow Control magazine. Contact her at [email protected].