Reliability in high-production sulfuric acid plants with vertical turbine pumps

More sulfuric acid is produced than any other manufactured chemical globally, making it one of the most important industrial chemicals. More than 50 percent of sulfuric acid produced is used in the production of fertilizers. Sulfuric acid is also used in the manufacture of many chemicals such as hydrochloric acid, nitric acid, sulfate salts, synthetic detergents, dyes and pigments, explosives and drugs. It is used in petroleum refining, processing metals and in lead acid batteries common in starting vehicle engines.

The production of sulfuric acid is accomplished through a liquid/gas contact process. Sulfur is burned to produce sulfur dioxide (SO2), which by using oxygen in the presence of vanadium oxide catalyst, is then oxidized to sulfur trioxide (SO3). The sulfur trioxide (SO3) is first dissolved in concentrated sulfuric acid to produce fuming sulfuric acid (oleum), which can then be safely reacted with water to produce sulfuric acid at a rate greater than the amount required to produce fuming sulfuric acid.

The production of sulfuric acid is a continuous process. It uses vertical acid pumps to pump the process acid to spray towers, contacting the liquid with gases as they flow through a combination of absorption and drying towers.

Vertical pumps are the industry standard because of plant safety and proven reliability. Any acid leakage from the pump is contained in the sump tank. No mechanical seal is present in the pump to fail and/or require replacement. A technical solution commonly found in the marketplace is an end suction pump mounted vertically. A column supports a volute casing and contains the shaft, which drives the impeller in the volute casing. A separate discharge pipe runs from the discharge of the volute to the top of the tank.

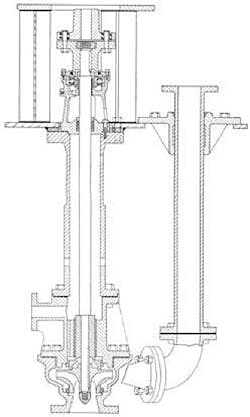

An alternative technical solution is also available. A vertical turbine pump is specially constructed and configured for continuous-duty, 24/7 pumping — a requirement in sulfuric acid production.

In the case of the vertical turbine pump, flow is from the pump suction through the impeller and directly up the column to the discharge flange before exiting horizontal. A noncontact labyrinth seal is present where the shaft penetrates the elbow at the top of the pump. Any leakage past the labyrinth seal is safely returned to the tank.

Configured for high reliability

The vertical turbine configuration provides several features that can contribute to high reliability in the pumping of sulfuric acid.

Concentrated sulfuric acid at 80 percent concentration has a specific gravity (SG) of 1.73 and 1.84 SG at 98 percent concentration. Mechanically speaking, the vertical turbine has a diffuser volute after the impeller, which results in no radial loads. Impeller wear rings and balance holes control the thrust loads. This is an extremely reliable and well-proven mechanical solution for extended mean time between maintenance (MTBM) in sulfuric acid applications.

Conversely, an end suction pump with a tangential discharge has low- and high-pressure areas in the volute, resulting in a radial load at the impeller. A dual volute with two cut waters in the casing may be used to somewhat balance the radial loads, but a radial load component is still present, which increases as the hydraulic components of the pump wear during normal operations. This wear results in higher radial loads, vibrations and reduced MTBM.

Concerning installation, the vertical turbine pump provides a compact configuration for mounting on top of the acid tank. It comes with a round mounting plate that can be bolted to the top of a tank. This mounting supports the mechanical drive assembly with the motor and discharge piping.

Sulfuric acid and the production of SO3 is exothermic and generates large quantities of heat. Sulfuric acid pumping applications commonly operate at elevated temperatures ranging from 230°F (110°C) to more than 480°F (250°C), which may be found in heat recovery systems. The hot acid flow traveling up a single vertical turbine column allows for evenly controlled thermal growth within the assembly. Dual columns with one partially filled with air and the other fully filled with liquid acid with different thermal expansions are avoided. In the case of the highest temperatures, a gas seal is added to the shaft to contain vapors and a fan to the mechanical assembly for cooling (see Figure 2).

Air-liquid interface

In addition to the mechanical benefits inherent to the vertical turbine design, a second important benefit exists.

Air-liquid interface points on the turbine design are limited compared to the conventional vertical pump. The air-liquid interface points, which will vary with changing sump liquid levels, are an area of increased corrosion wear for vertical sulfuric acid pumps.

Why is this the case? Sulfuric acid characteristics such as density, viscosity, vapor pressure and resulting corrosion characteristics vary greatly with changes in concentration and temperature. For example, high-concentration, 99 percent sulfuric acid may be pumped using cast-iron materials, however, reducing concentrations of sulfuric acid to under 95 percent concentration can require special alloys. Even at the highest acid concentrations, higher corrosion rates on the pump’s components are found at the air-liquid interface areas.

Therefore, it is common for sulfuric acid plant maintenance personnel to monitor metal thicknesses on the columns of sulfuric acid pumps. If improperly monitored and components are not replaced ahead of time, a catastrophic failure can occur.

For pump reliability, it is critical to consider the operating conditions of temperature and the concentration of sulfuric acid when selecting sulfuric acid pump materials.

Conclusion

In conclusion, for sulfuric acid applications, the vertical turbine pump offers many benefits that can result in increased MTBM.

The compact design with single-column discharge handles thermal expansion in the assembly. The elimination of radial loads and controlled thrust loads provides a mechanical solution that becomes more important as flow rates increase to higher levels, which is an industry trend in new sulfuric acid plants. The reduced air-liquid interface points are critical to reduced areas of corrosion on the pumps. And finally, when required, it is an easy assembly on which to perform maintenance.

Dave Krebs is the U.S. business development manager for Sulzer Ensival Moret. He has more than 25 years of international field sales experience in energy, fertilizer, mining and chemical processing markets. Krebs has contributed to the Hydraulic Institute’s ANSI standard; Rotodynamic Centrifugal Slurry Pumps and is a member of the Society of Mechanical Engineers. He has presented at the Ammonium Nitrate Nitric Acid Conference and the AIChE Central Florida Section’s Annual International Phosphate Fertilizer & Sulfuric Acid Technical Conference. Krebs can be reached at [email protected].